In a home workshop, a circular saw will occupy a special place. The fact is that it is he who will play the most important role in all work related to wood processing. A circular saw for wood will perform most of the operations of cutting wood, leveling and adjusting the size of planks. In fact, all work related to wood processing will begin with it, however, provided that the equipment is selected correctly according to its parameters.

Design features of circular machines

To thoroughly understand what a circular saw is and what functions it can perform, you need to understand the principles of its operation and what parts it consists of. The operating principle of a circular saw is to use a rotating circular saw mounted on a stationary bed. The working body is a saw blade - a steel disk with teeth that have one-sided or multi-sided sharpening, used for cutting wood, chipboards or other wood materials. Unlike hand-held circular saws, a circular saw in most cases uses a belt drive, which increases the capabilities of the machine during operation.

The basis of the device is the frame - a monolithic or prefabricated structure that serves as the basis for mounting an electric motor, a working shaft with knives, a saw blade and other structural elements or devices, for example, a carriage. It is worth mentioning right away that most designs use an electric motor, but there are exceptions, for example, devices with a gasoline or diesel engine. There are few such devices, but they exist and are used to work in places where there is simply no electricity.

In addition to purely circular saw machines, there are many tools with an extended shaft on which planing knives are mounted. Such devices, by analogy with hand tools, are called a plane or jointer. The plane has a small width and length of the working plate, which is why it can only plan small planks and boards. The jointer is another matter - its width can be 200, 250, or even 400 mm. And its working plate is much longer, so achieving high quality of the workpiece on a jointer is much easier and more convenient.

Advantages of a multi-saw machine over a frame saw and band saw

The twin-shaft saw has many advantages compared to other types of equipment. First of all, it is endowed with the highest cutting speed. This allows you to increase the productivity of the entire production.

Multi-saw machines are reliable and durable, which allows you to save on preventative maintenance and repairs: they wear out more slowly than alternative options. Their productivity is many times greater than that of frame saws and band saws.

The relatively large cutting width is compensated by good geometric parameters of the finished material. This allows you to reduce allowances for further processing. Taking this factor into account, disk and belt machine equipment produces an equivalent material yield.

The maintenance costs for saw blades are approximately equal to the costs for frame equipment, and also several times less than for band saws.

For large factories, the use of disk saws is the only way to constantly produce the required volume of products.

Compared to other types of units, multi-saw woodworking machines are considered the best choice: they guarantee high product quality, are reliable, have a long service life and high throughput.

Purpose

Circular saws are mainly classified as woodworking machines, but they can be used to cut plastics and even asbestos-cement boards. But still, they are intended for sawing boards, cutting chipboards and fiberboards, as well as plywood.

Household, however, as well as professional machines can be:

- Portable;

- On a stand;

- Stationary.

To perform simple operations with small workpieces, only a saw is usually used, without additional equipment or accessories. But for such work as cutting chipboard slabs, it is also necessary to use a carriage or a special format table in the machine kit to cut a dimensional sheet of material.

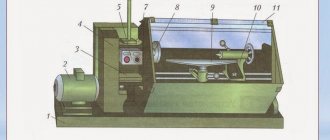

Ts6-2 Arrangement of components of a circular saw universal machine

Arrangement of components of the circular saw universal machine Ts6-2

List of components of the circular saw universal machine Ts6-2(K):

- Bed - Ts6-2(K).10.000

- Caliper Ts6-2(K).20.000

- Lifting mechanism Ts6-2(K).30.000

- Carriage Ts6-2(K).40.000

- Guide ruler Ts6-2(K).50.000

- Fencing Ts6-2(K).60.000

- Electrical equipment Ts6-2(K).80.000

Types of circular machines

There are several classifications of circular machines. The first and most significant is the history of the origin of the equipment. It may look unusual, but this is exactly the one with which you should start getting acquainted with the types of equipment:

- Industrial production machines;

- Handicraft machines.

Equipment manufacturers, in turn, divide machines into the following classes:

- Portable machines;

- Machines using supply;

- Stationary circular saws.

By purpose, the equipment can be divided into:

- For machines of universal household use;

- Professional machines.

Depending on the tasks that the device can solve, the following classification can be made:

- Circular saws for longitudinal cutting;

- Circular saw with cross-cut carriage;

- Multifunction device;

As for the size, it can be a mini version of the circular saw for use in an apartment or house, or it can be a portable model for installation on a table or on a special stand. Or there may be a full-size model that requires installation on a specially prepared foundation.

Thanks to its small size, this mini tabletop circular saw can be used as the main equipment for modeling or creating crafts. A format circular saw usually has impressive dimensions and is designed for cutting sheet material. For universal and multifunctional models, the presence of auxiliary equipment plays an important role, allowing you to make not only longitudinal, but also transverse cuts of the material.

Possible malfunctions and their causes

As already mentioned, a circular multi-blade machine requires careful handling during operation, and when you identify the first signs of a problem, you should immediately contact professional craftsmen if it is impossible to correct the situation yourself. The most common problems encountered are:

- Uneven cut. It is necessary to adjust the position of the saw blades;

- Stop feeding the workpiece. Most often, the cause of this problem is incorrect adjustment of the feed rollers or incorrect pressure of the pressing rollers;

- uneven sawing of boards. It is necessary to adjust the location of the guide rail;

- when the caliper moves jerkily, it is necessary to inspect the hydraulic system (air penetration is possible) or the oil level (if the amount of oil is low, it should be added);

- The dimensions of the finished product at the outlet are not maintained with the specified accuracy. To resolve this problem, you need to secure the end stop.

It doesn’t matter what type of saw you bought and use in your work, only constant and timely maintenance of the unit will prevent its serious breakdowns. Proper operation of the equipment in accordance with its characteristics is also important. Improper attitude to work leads to serious damage.

How to choose a circular saw

The main criterion for choosing equipment for a home workshop should be the feasibility of purchasing this equipment. For the home, a device with small dimensions and a large number of functions is considered the optimal choice.

For use in a small workshop, you should pay attention to a planing and sawing machine with the ability to cut material up to 125 mm. The frame of such a device is recommended to be cast iron, and the engine should have a power of at least 2.2-2.4 kW.

For beginners, it is recommended to purchase a tabletop version of the circular saw or a model with a stand. And even if the cutting depth is only 85-100 mm, it will be enough to develop skills in working with such a device.

Regarding the choice of engine power, it is recommended to pay attention to equipment with an engine from 1.1 kW.

As for the current consumption, for those who have experience working with such machines, it is better to choose machines operating from a three-phase network of 380 V, and for beginners, a household network of 220 volts is sufficient for simple work.

Multi-rip single-shaft machine KS-1000

Official company page: Machine KS-1000

was founded in 1996. This is one of the largest similar enterprises in Russia, producing more than 50 model ranges of machines under the trademarks Altai™, White Shark™ and others. The equipment is certified for sale in the Eurasian Economic Union.

The edge-cutting machine KS-1000 is designed for longitudinal sawing of unedged boards and slabs in order to obtain edged lumber (edged boards, slats, bars, three-edged slabs).

Characteristics:

| Specifications | |

| Options | Meaning |

| Number of drive ripples, pcs. | 4 |

| Maximum cutting height, mm | 100 |

| Maximum distance between extreme saws, mm | 940 |

| Feed speed change m/min | from 0 to 40 |

| Saw diameter, mm | 250…350 |

| Saw mounting diameter, mm | 75 |

| Setting the minimum board thickness | screw |

| Blade spacing settings | adjustable with spacers |

| Saw drive motor power, kW | 22 * ,30,37,45 * ,55 * |

| Feed motor power, kW | 1,1 |

| Transport parameters: | |

| — height, mm | 1300 |

| — width, mm | 1600 |

| — length, mm | 2000 |

| — total weight, kg | 1400 |

| - volume, m3 | 4 |

Price:

Such a machine costs from 400,000 rubles.

Advantages:

- High cutting speed

- Ideal geometry of the resulting lumber

- Up to 10 saws on the shaft

How to make your own circular saw for home

Theoretically, you can make any machine yourself, provided you have all the spare parts and equipment for the job. But in order to assemble a home circular saw, and even with the function of planing wood, you must first of all purchase a working shaft. This is the most important and expensive element of the design.

The fact is that it is extremely difficult to make such a shaft yourself without a lathe and milling machine. The shaft is not only machined with great precision, but after installation on the supports it is centered and aligned. At a rotation speed of 3000 rpm, the shaft should have minimal or no runout. But if it exhibits noticeable beating, it may cause device failure or even serious injury.

The second important element of the machine is the electric motor. It is selected depending on the diameter of the saw blade. The larger the diameter of the disk, the more powerful the engine needed. For modeling, you can take a 450 W motor, but in this case the disk diameter should be no more than 100 mm. For a disk with a diameter of 150-160 mm, a motor with a power of 1.6 kW is required; for a circular saw with a diameter of 170 mm, a power of no less than 2.0 kW will be required.

For the design of the frame, a steel angle or channel is selected. If the circular machine is planned to be stationary with a powerful engine and a large disk, then the design should be massive. Therefore, the corner must be no less than 60x60 mm or a channel with a width of 60 mm or more.

A belt drive is used to transmit rotational motion from the engine to the working shaft. Here it is better to use a V-belt. You can try a flat belt, but a V-belt is still considered the best option for use in such a homemade product.

The slab should be as smooth and durable as possible. Therefore, in order to make a desktop, it is recommended to choose a metal plate with a thickness of 4-5 mm. Before installation on the frame of the bed, the plate must be checked and aligned.

It is especially necessary to focus on security issues. First of all, this concerns the controls - the electrical equipment unit must be carefully insulated, and the switch must have an emergency shutdown button. It is recommended to install a limiting device above the saw, similar to industrial designs, so as not to accidentally get your hand into the saw blade. In addition, the pulley and belt drive must be covered with a protective cover.

Multi-saw twin-shaft machine MDS-250

Official company page: MDS machine

Stankocenter Perun is another Russian company that produces machines of various types, as well as tools and components.

MDS-250 is designed for longitudinal sawing with circular saws of two-three-four-edged timber into boards or edged timber and cutting boards into blanks of a given thickness with mechanized feeding.

The machine can be equipped with electric motors of various powers from 30 to 90 kW. There is a belt conveyor for removing sawdust with an aspiration pipe.

Characteristics:

| Maximum timber thickness, mm | 170/130 | 210/150 | 250/150 |

| Maximum beam width, mm | 700 | 700 | 700 |

| Minimum beam length, mm | 1500 (1200 option) | 1500 | 1500 |

| Diameter of saw blades on the lower shaft, mm | 300-400 | 350-450 | 400-450 |

| Diameter of saws on the upper shaft, mm | 300 | 350 | 400 |

| Saw shaft diameters, mm | 75 | 75 | 75 |

| Distance between extreme saws, mm | 610 | 610 | 610 |

| Speed of saw shafts, rpm | 3800(3350 option) | 3350 | 3350 |

| Saw shaft motor power, kW | 22, 30, 37, 45, 55 on request | 37, 45, 55, 75, 90 on request | 45, 55, 75, 90 on request |

| Feed speed, m/min | 3-30 (5-40) | 3-30 (5-40) | 3-30 (5-40) |

| Feed motor power, kW | 4 | 4 | 4 |

| Machine dimensions, LxWxH, mm | 3250x2250x1700 | 3350x2250x1750 | 3350x2250x1800 |

| Approximate weight, kg | 3300 | 3650 | 4000 |

Advantages:

- Infinitely variable electronic feed speed control

- Sawing speed up to 40 m/min

- Two multi-row chain conveyors along the entire length of the machine

Rules for safe operation

A circular saw is one of the most dangerous types of home equipment. Before starting work, it is necessary to clear the working space around it and check that the device is securely installed on the frame.

When working, it is recommended to have clothing that protects your arms and legs. To protect your eyes and face, you must wear a protective mask or safety glasses.

For sawing wood, take pieces no more than twice the length of the working surface of the circular saw. If there is a need to process workpieces of greater length, then a longitudinal feed carriage is mandatory.

It is important to remember that the engine is turned on first, and then the workpiece is brought to the saw blade, and not vice versa. You need to work on the machine from the side where the power button is located.

By following these simple rules, you can quite easily select the optimal equipment option for your home and in a short time learn how to perform several technological operations.

How to use a multi-saw correctly

Due to its high productivity, the circular multi-blade machine requires careful and careful handling. Beginners often encounter the fact that the discs begin to “burn,” smoke appears in the room, and the cutting elements quickly become dull and deformed.

The reason for this situation may be the use of low-quality parts or incorrect setting of the sharpening angle of the cutting edge of the saw blade. An excess of wood supply speed may also be the cause.

The electric drive and the disk are connected by a belt, which provides torque to the shaft. The belt itself is also a kind of “fuse” when the disk jams (it slips and protects the electric motor from overheating and damage to the circular saw).

Remember that domestic belts are not suitable for imported multi-saw machines, that is, changing imported ones to domestic ones will not work, since manufacturing plants produce belts of different standards. Accordingly, imported sawing equipment requires more maintenance and repair costs. The difference in the form of belts reduces the efficiency of the unit due to power loss (the power of the electric drive of industrial designs ranges from 60 to 100 kW).

Before starting work, you need to check the tension of the belts, since their significant stretching leads to rapid wear of the supporting element of the rotation mechanism. The machines are available in configurations with an auxiliary support and a longer shaft; their price is slightly more expensive, but they are distinguished by their greater throughput when sawing wide wood.

In our production, up to 15 cubic meters of sawdust were produced in one work shift; not every workpiece processing workshop will be able to realize such an amount. Also included in the waste are the edges of the workpiece, which are cut off by the side discs. More on this in the next chapter.