In this article we will look at step-by-step master classes on how to make a rocking chair with your own hands from wood, metal, plywood, and wire spools. The rocking chair, manufacturing, drawings, layouts and assembly diagrams, which we will consider below, also includes a rocking chair and a chaise longue for the garden.

Finishing

As for the finishing of a plywood chair, it all depends on the scope of its use. If furniture is made for use in the yard, it must be treated with antiseptics and covered with paints and varnishes . If the chair will be in the living room by the fireplace, it should be given a more noble appearance. To do this, the product can be upholstered with velor or artificial leather . The fabric must be nailed to the frame with small nails, starting from the back.

If you don’t want to deal with the labor-intensive process of upholstering a chair, you can sew a removable cover on it. For this purpose, durable and pleasant to the touch fabric and foam rubber are used.

Tip : you can also make a children's or adult table and even a cabinet from plywood. And next to the rocking chair you can put a glass table, coffee table or laptop table.

Materials and tools

To make a rocking chair from plywood, you will need:

- blueprints;

- graph paper and pencil;

- several sheets of plywood 1520*800 mm (the exact quantity depends on the design of the chair);

- jigsaw;

- primer, paint, paint brushes;

- fine- and medium-grained sandpaper;

- wood glue;

- milling cutter;

- drill with a set of drills;

- fasteners (wood screws, nails);

- screwdriver or hammer;

- rags;

- plugs for screws;

- scissors;

- mechanic's knife.

Assembly of the structure

To connect the elements of the rocking chair into a single structure, glue and fasteners are used. Due to the high load on furniture, glue alone will not be enough. Nails or wood screws can be used as fasteners.

The parts of the rocking chair are coated with wood glue in places of contact with each other, then additionally fixed with fasteners. The screws are screwed in all the way, slightly recessing the heads into the plywood. The nails are also driven in so that the head is immersed 1 mm into the material.

Finished plywood rocking chair

Excess glue that appears at the joints of parts should be immediately removed with a clean rag - when the composition hardens, it will be difficult to remove it.

After this, the plywood rocking chair must stand for at least a day so that the adhesive composition completely hardens.

List of favorite materials

Selecting the material is the first stage of consideration, because the rocking chair must be very reliable, durable, but light, since the owners will quickly get used to “carrying” this furniture around. Therefore, more often the gaze stops at plywood, wood, and vines. Metal also often joins this list of rocking chair candidates.

- Plywood. Such furniture will be practical, light, beautiful, but it has a significant drawback - the fear of water. Therefore, a rocking chair “resting” in the open air must be closely monitored, since the sudden onset of rain is a big threat to it.

- Wood - beech, oak. Correct pre-processing of this material is the key to the durability of the product. What is attractive about it is its environmental cleanliness and excellent appearance. The main requirement is minimal carpentry skills, as the work is not that simple.

- Loza is a leader if we consider furniture from the point of view of lightness and beauty. Fastening elements do not take part in the creation of furniture, since when weaving, glue becomes the only assistant. Disadvantages: fear of moisture, fragility, labor-intensive.

- Metal is an almost eternal material. For all its positive qualities, it has a huge drawback - heaviness. In addition, such a massive rocking chair can present an unpleasant surprise - it can tip over, and this can lead to serious injuries.

There is another material that is attractive due to its low price - plastic, but for self-production you need special equipment; the strength of such a design is not up to par. For the frame and runners of rocking chairs, they often prefer to use profile or plastic pipes.

You can also compare prices for rocking chairs:

Final balancing

When the chair is ready, they carry out a routine check of its functionality - rock it and observe the smoothness of movement. If there is a list or uneven roll, most likely the cause is uneven skis. To stabilize the situation, additional balancing will be required:

- when leaning forward, the back is made heavier by attaching the bar to the rear runners;

- to increase the weight of the product, decorate the required side with weighting decor;

- in the case of a roll back, a counterweight is installed in front in the form of slats under the feet or niches.

Many people dream of a rocking chair, as it is an ideal place for relaxation and good rest. Only in it is it possible to step away from everyday problems and immerse yourself in dreams near the fireplace or in the garden. And you don’t have to spend a lot of money to do this. It is enough to show your creativity and set aside a little personal time to make an exclusive rocking chair with your own hands. And using ready-made diagrams and drawings this is easy to do.

How to choose?

When choosing plywood to create original and practical furniture, you should pay attention to the following nuances :

- environmental friendliness and pleasant structure;

- material thickness;

- the presence of cracks, chips and other defects on the surface.

Attention : if the plywood thickness is 1.5 mm, it is recommended to process it with hand tools. If you choose 6mm plywood, power tools are suitable for processing.

Design features and product types

A rocking chair is a comfortable piece of furniture for relaxation with the ability to rock a seated person due to the special shape of the legs or the action of hinge mechanisms. It successfully combines decorative and useful functions. The scope of application is almost universal. Rocking chairs are installed in living rooms, recreation areas, bedrooms for nursing mothers, in work rooms, on piers for fishermen, terraces, and gazebos.

Depending on the design, there are:

- Classic rockers on radius runners with a relatively small radius of curvature. These models can be made with your own hands in a matter of hours; there are no complex elements in the design. Such furniture is appropriate in any type of interior; the only disadvantage is considered to be poor stability. To eliminate this drawback, the seat position is made low.

- Rockers with variable curvature of runners. The arches of such models have bumpers that reduce the risk of overturning to a minimum. This option is ideal for high-rise designs and models for nursing mothers. It is not difficult to make such rocking chairs with your own hands; there are no problems with the selection of materials and drawings.

- Elliptical chairs with drop or oval arches. Provide a pleasant swing and are compatible with many types of classic or modern interiors. Making such arcs at home requires some skill; in the absence of experience and high-quality materials, they should be purchased ready-made. The stability of the structure depends on the presence or absence of fenders.

- Pendulum chairs (gliders). These models have stable legs and a pendulum mechanism that provides a pleasant, safe and silent swing. When making a pendulum rocking chair with your own hands, the glider hinges are attached to the fixed legs. The length of these elements is selected based on the expected swing amplitude (it is difficult to carry out this stage yourself without the appropriate experience). Factory pendulum models are superior to homemade ones in functionality. They are equipped with clamps for adjusting the height of the rocking chair, retractable footrests, and mechanical or touch control units.

- Multifunctional “3 in 1” models, equipped with special legs and mechanisms that allow you to fix the product as a lounger, regular or rocking chair. Despite all the advantages, such furniture is expensive and takes up a lot of space. Changing modes is often accompanied by jerks.

- Spring models with steel springs holding reclining round seats. As a rule, they are equipped with an inertial rocking mode and are made of thick wicker, rattan or stainless steel. This product does not have swinging runners or a pendulum part, the design is convenient and safe. It is difficult to make such a chair with your own hands without a reliable spring base.

- Tumblers, which have a one-piece design, easily take a lying position. Homemade rocking chairs of this type are assembled from plywood elements; factory ones can be made of plastic or molded polyethylene.

- Suspended structures on static supports. The seats of the chairs with this design are suspended on chains or hooks. The model looks original and stylish.

Modifications and features of the Poeng chair from Ikea, pros and cons of the product.

Swinging furniture for children is included in a separate category. The baby seat can be in the form of a reversible car, rocking horse or crib. Such products are made from natural materials and painted in bright colors.

"3 in 1"

With variable curvature of runners

Classic

Pendulum

"Tumbler"

Suspended structure on static supports

Spring

With drop or oval arches

Children's rocking chair

Schemes and drawings

When making garden furniture, the following recommendations regarding its dimensions must be observed.

- The sizes of stainless steel screws are 51*8 (similar ones can be used).

- Dovetail nest, in which the armrests rest on the front and rear legs - 10*19*102 mm.

- A 3 mm chamfer is removed on the edges of all parts.

- The hole into the center of which the self-tapping screw is screwed widens to 19 mm at the surface of the part, turning into a narrow part and deepened to 5-10 mm. It will be easier to tighten the screws and cover these places with varnish (if plugs are not used).

- Rear legs: 2 pieces, 20*254*787 mm each. Front – 20*76*533 mm.

- Chair back: 20*279*914 mm.

- Armrest supports: 2 front 20*127*406 mm, rear 20*76*610 mm.

- Jumper: 20*51*589 mm.

- Insertion strips: 2 pieces, 12*20*254 mm each.

Different design options - folding or regular, differ in the size of the parts. The chair must be reliable, not break or squash under tens of kilograms of weight, which account for a significant part of the body weight of a large person.

Examples of rocking chairs

Metal

Let's start our review of rocking chairs with metal ones, because... making rocking chairs out of it is justified in few cases. Forged rockers, imitating classic wicker ones from wicker or rattan, as requiring special equipment, a forge, etc. We don’t touch qualifications. But a metal rocker “like a braid” can be made by welding from a profile pipe; preferably elliptical section. In this case, you need to choose the kinematic diagram of the nirvana rocking chair as the least sensitive to the excessive elevation of the CO above the CO; it also corresponds well in design to wicker rocking chairs, see Fig. In order not to increase the moment of inertia, the seat is made of braided cables, belts, etc.

Welded Metal Rocking Chair

It also makes sense to make garden tumbler rockers from metal, see below, due to its strength and resistance to wear. But a welded frame like the one in pos. 1 pic. on the right – the solution is not optimal, it is too complex, labor- and material-intensive. It is much easier to make a steel frame for a garden rocking chair of the Concept type, pos. 2. Pipe – round from 40x2. The bed itself can be sewn like a hammock; balancing - by changing its tension and, accordingly, sagging. As a result, the work and costs are much less than repeating the established forms of rocking chairs that come “from the tree,” and the comfort is no worse.

Designs of garden rocking chairs made of steel pipes

Here we can see another interesting option: the frame of a rocking chair Concept made from... gymnastic hoops. Just not aluminum or propylene, but carbon fiber (carbon). Strength is monstrous, durability is absolute, weight is negligible. The same cannot be said about the cost, however.

Vanka-Vstanka

Recently, garden rocking chairs - tumblers - have gained popularity. If you lean back completely in this one and tuck your legs, it falls back almost 90 degrees without losing stability; the rider will find himself lying on his back with his knees at the zenith. And if you stretch your legs forward, the rocking chair-vanka-stand-up becomes its normal position and then you can rock as always.

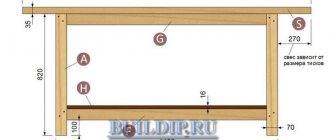

Sidewall of a garden rocking chair-lounger

The Vanka-Vstanka toy with a spherical bottom sways quite sharply. Comfortable rocking of the tumbler rocker is achieved by profiling its runners according to a complex law. It will not be possible to build their sidewalls “school style”, as described above. You need to be guided by proven samples and draw markings on the grid, see fig. The inset version, with cladding made of planks 30-40 mm thick, is more expensive, but less labor-intensive. It also allows you to increase the length of the rocking chair by installing intermediate supports-runners.

Note: wooden balls are placed on the protruding ends of longer rods (1050 mm) and form handles for rocking and carrying.

Rocking bench

Rolling your heels into the sky, throwing your hands behind your head and admiring the clouds floating in the blue heights through the fluttering foliage is a heavenly pleasure, but it doesn’t suit everyone. Some people want to look more impressive while relaxing. A garden bench or rocking chair is more suitable for this type, see fig. It is a little difficult to swing on it, its own moment of inertia is large, but it also swings for a long time. The maximum span between supports with runners is 750 mm with cladding made of 40 mm thick slats. The back covering is decorative.

Garden rocking bench

Sun lounger with awning

Both those and other requests will be satisfied by a garden rocking chair on elliptical runners and with an awning. The dimensions of its sidewalls are given in Fig. their material is 24 mm plywood. The width of the bed is up to 900 mm, its covering is made of 50x50 slats. The sidewall areas, indicated by gray circles, are connected by round wooden crossbars with a diameter of 60 mm or more.

Dimensions of the sidewall of a rocking chair with an awning

Rocking chair

We are not talking about rocking horses here; they are toys, not furniture. But it’s also not harmful for children to rest while rocking, so it makes sense to give your child a rocking chair. Its proportions will be slightly different than for adults, due to the influence of the square-cube law.

Design and detailing of a children's rocking chair

The structure of a children's rocking chair, its assembly diagram and specification of parts are shown in Fig. material – wood. It will not be difficult for a more or less experienced home craftsman to build a rocking chair for a child, guided by these data, and beginners can first watch a master class on making almost the same children’s rocking chair.

Finishing

Having completed the assembly, they move on to finishing.

A plywood rocking chair is decorated using:

- clear varnish;

- alcohol- or water-based stains;

- paints;

- oil or water based varnishes.

Another option is to cover the seat and back with fabric. After the finishing of the plywood rocking chair is completed, the caps of the fastening elements are closed with special furniture plugs. It is permissible to use instead a sealant that matches the color of the surface of the chair.

Rocking chair made of plywood with metal crossbars

Some general information

Whatever one may say, it is a rocking chair, especially one standing in the garden or near a lit fireplace, that many associate with comfort, a pleasant evening in a narrow family circle, peace and quiet.

In such an environment you can have a great rest and relaxation by reading your favorite book or watching a good movie. The rhythmic rocking movements of the rocking chair will help you get ready for sleep and simply feel peace, which is so rare in modern life, filled with bustle and heavy thought processes.

Rocking movements increase concentration

It is still unknown exactly how and where the very first rocking chair came from. Usually many people associate it with old England, fireplaces and rugs. At the moment, there are two main versions of the history of the origin of this chair.

According to one of them, the first rocking chair was invented by the Viennese furniture maker, experimenter and innovator, as well as a fan of bent wood, Michael Thoneta in the mid-19th century. However, there is one more fact that casts doubt on this version. Thus, at the end of the 18th century, the word “rocking chair” was added to the English dictionary, and since the 1800s, such chairs began to be produced by many English furniture manufacturers.

But the fame and peak of popularity of rocking chairs came precisely in the 19th century. They were used mainly by rich and aristocratic people, as well as those involved in literary and artistic arts.

According to the second version, the rocking chair was invented by Benjamin Franklin. In terms of time, this was also the 19th century. But there are those who refute this version, believing that Franklin was just the one who became the first owner of the rocking chair.

In a word, we can say that the beginning of the history of the chair is the 18th-19th centuries. The sources are silent about the rest. And, nevertheless, rocking chairs still remain popular and in demand, and are primarily intended to create a special ambiance and comfortable environment in a certain place.

The rocking chair has its own history

Where can it be used?

A rocking chair in general can be installed anywhere, be it a room or a veranda in the garden. But most often it can be seen in a spacious living room in a private house or in the garden. In the latter case, rocking chairs are often made of either metal or rattan.

The products are characterized by increased strength; when properly processed, they are not afraid of water, are durable and can really not only decorate the garden, but also create a real relaxation area in it. Moreover, the rocking chair will feel great both on the veranda and on the lawn or garden path, where it will not disturb anyone.

Also, rocking chairs fit perfectly into the interior of large and spacious rooms, especially those made in a certain style. Of course, with modern design solutions, you should abandon the traditional rocking chair, but a stylized chair will fit even into a high-tech room.

Types of rocking chairs

A rocking chair is a comfortable, useful item that can be easily placed in almost any room or even a country garden. Such furniture is used mainly for relaxation of people of different ages.

Main types of swinging chairs:

- massage – used for healing, as it is equipped with massage rollers and vibration elements;

- on radius runners - the most commonly used option, as simple as possible to assemble, but if it swings too much, such furniture will fall;

- on elliptical skids - the product is equipped with bumpers that prevent it from tipping over;

- with variable curvature - almost any landing height is allowed here, the likelihood of an object overturning is low;

- multifunctional - this is a “three in one” design, with an adjustable backrest, which can be converted into a bed if necessary, therefore it is used only in large rooms;

- glider is an item of increased comfort that has a special footrest, soft armrests, and other elements.

A wicker rattan chair will become an indispensable attribute of a country veranda, a soft one, upholstered in leather, will be located in the office relaxation area.

Advantages of a homemade plywood rocking chair

Excellent pattern of wood fibers - natural decor of plywood chairs

Using plywood as the main material for furniture assembly guarantees the following advantages:

- Making furniture with curved shapes . Plywood, unlike solid wood, can be bent in different directions, giving products complex curved shapes.

- Ease of manufacture . Most plywood furniture can be made by yourself using available tools from your home workshop.

- Affordable price . Finished products will cost less than similar, but solid wood products.

- Great appearance . Plywood is glued from veneer with a solid pattern, and therefore the finished furniture looks no worse, and sometimes even better, than similar products assembled entirely from wood.

- Strength and durability. Due to the special arrangement of veneer in the board, plywood demonstrates higher fracture strength in comparison with similar indicators of solid wood.

- Environmental Safety . Multilayer plywood is a product made from natural raw materials - wood, and therefore this material is safe for humans.

Types of rocking chairs

What kind of chairs can be made from multi-layer plywood? There are many options, let’s consider only the most interesting.

Models in which curved runners and railings form a single piece

Plywood chair mounted on bent skis

3D chair assembled from several blanks of different shapes, connected in a pack through identical spacers

Another version of a 3D chair, but assembled from parts of the same shape

The triumph of minimalism - designer furniture assembled from two bent pieces of plywood

The minimalistic design consists of a pair of identical plywood sidewalls - runners, connected to each other by transverse crossbars

Another example of minimalism is a chair made of 4 parts, namely, the design consists of two sides of the seat and a backrest

Chair-bed with curved runners

A rocking chair with a pendulum mechanism ensures uniform swinging with less force.

The bowl chair is made from strips of plywood, which act as bent runners

Suspended models are mounted using cables on a stand or on a hook embedded in the ceiling structure

How it swings

From the review it is clear that in terms of design, all rocking chairs come in 3 types, namely, models with bent runners, models with a pendulum and hanging models. But regardless of the modification, the principle of swinging of all rocking chairs is pendulum.

The seat in all of the listed models moves due to a forced shift of the center of gravity relative to its original position. Subsequent displacements occur by inertia. As it swings, the inertia weakens and the pendulum stops until you set it in motion again.

Drawings of a plywood rocking chair

When choosing a chair model for self-assembly, we give preference to those drawings that will be easier to translate into reality. I offer several such drawings.

Living room armchair with soft seat back and armrests

The drawing shows a model of upholstered furniture assembled on solid sidewalls, cut to the shape of curved runners, turning into armrests. To connect the sidewalls, you can use transverse inserts made of plywood or planed boards.

Country double rocking chair made of combined materials

The supporting frame of this chair is assembled from plywood parts. There are cross slats on top of the frame. The lower part of the sidewalls is reinforced with a bent strip of runners. This design will be an excellent element of the surroundings of a country terrace or personal plot.

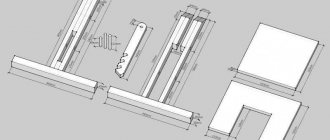

Collapsible plywood chair

I recommend paying special attention to this drawing, since assembling this furniture is not easy, but very simple!

Puzzle Rocker translated from English means “rocking chair assembled from mosaic fragments.” 4 fragments shown in the diagram are cut from multilayer plywood. Then these fragments are put together without the use of fasteners and the chair is ready. If necessary, the rocking chair is easy to disassemble.

Design requirements and dimensions

The dimensions of plywood furniture are selected so that the overall dimensions correspond to the thickness of the material used. That is, the larger the chair, the thicker the plate from which the parts will be cut should be. The preferred option for any chairs is plywood with a thickness of 25 mm or more.

What you need for work

The most important tool for working with plywood is a jigsaw, which will ensure sufficient accuracy of the cut.

Required materials and tools:

- Multilayer plywood - thickness 30 mm.

- Fasteners, wood screws and other hardware for furniture assembly.

- Wood glue.

- Paints and varnishes for decorative and protective finishing of furniture.

- Jigsaw.

- Screwdriver with a set of drills and bits.

- Wood clamps.

- Sander or hand grater with replaceable sandpaper.

The process of creating a chair

Side element in the design of a seat mounted on a pendulum

Making furniture from plywood is not much different from making chairs from other board materials. The process is gradual and all stages are performed in the following sequence:

- Cutting the material in accordance with the selected drawing.

- Preparation of parts - chamfering, drilling holes, forming grooves, etc.

- Furniture assembly.

- Finishing, including sanding and treatment with paints and varnishes.

Let's consider the above points in more detail.

Tips for selecting and preparing plywood sheets

Plywood sheet with standard dimensions 1.22×1.5 m

If the material is purchased for subsequent painting, simply select a sheet of the required thickness, not paying attention to the texture of the fibers. If the finished furniture is supposed to be varnished after assembly, we don’t skimp and purchase the plywood that initially looks good.

We try to purchase material that has been stored correctly - we are talking about humidity and the absence of sheet curvature. The purchased material must be smooth and dry. Pay attention to the cut line; all layers must be tightly glued together without peeling.

Preparation of plywood and general rules for working with it

The cut of the slab clearly shows the location of the layers of veneer and glue.

Plywood is a board glued together from sheets of natural wood veneer. On the one hand, the layered structure of the material simplifies the work, since plywood can be bent.

Despite the large teeth of the disk, the circular saw ensures highly accurate cutting

On the other hand, this feature makes sawing difficult, since an incorrectly selected tool and unprofessional cutting lead to the veneer layers cracking and crumbling along the cutting line of the slab. That is why, when assembling furniture from multi-layer plywood, we follow the instructions and recommendations proposed in this article.

The photo shows an example of plywood bending due to non-compliance with the humidity level in the room

How to prepare material for subsequent sawing? You don't need to do anything special, just make sure the slab is dry enough and doesn't have any curvature. If there is curvature, lay the plywood on the bars so that the sheet bends in the direction opposite to the curvature.

Making patterns and transferring drawings

Appearance of the finished chair, plus templates for cutting parts

Once we have decided on the choice of drawing, all that remains is to mark the slab in accordance with it. That is, you need to transfer the drawing to plywood, while increasing the scale of the image to natural size. If the design of the furniture to be assembled does not have complex shapes, the drawing from the paper is transferred along a ruler and square.

If you plan to make furniture with complex shapes, for each piece, patterns (templates) are cut out of thick paper or cardboard, which are subsequently traced on a sheet of plywood.

Sawing plywood into parts

For curved cutting, it is preferable to use a jigsaw, since the tool is accessible. If possible, the workpieces are cut on a band saw, provided that a blade with a fine tooth is used.

To make sawing convenient, glue the template directly onto the plywood.

After the parts are cut, we put them together and check the coincidence of the perimeters; if there are protrusions, we immediately sand them

To ensure that the finished furniture is neat, it is preferable to sand the plywood blanks and varnish them before assembly.

Assembly of the structure

The photo shows that in the most loaded areas of the chair, connections are made using bolts

The chair is assembled in accordance with the drawing. The strength of the finished product largely depends on the choice of fastening hardware. To achieve maximum reliability, we use self-tapping screws only in unloaded connections. In areas with a high degree of load, we use fasteners consisting of bolts and nuts.

The advantage of a bolted connection when assembling furniture is that the nuts can be tightened during use and thus eliminate play and creaking.

Final balancing

Factory made plywood runners for rocking chair

How to balance the runners for smooth rocking? Make sure there are no protrusions or flat areas on the runners that could prevent them from swinging. If there are such areas, round them using a sander and sandpaper.

In addition, to ensure smooth rocking without jamming, use the chair on flat, hard surfaces. If the furniture is to be used on a personal plot, it is preferable to make the runners wide so that they do not press into the ground.

How to bend plywood for a rocking chair

How to make curved parts from plywood without cutting out their outline from a single sheet, but by bending strips along a given radius?

| Illustrations | How to bend |

| Steaming and bending . This is a classic method in which the part is soaked in boiling water, and then molded and fixed according to a template. After drying, the workpiece retains the specified radius. The method is relevant for thin plywood. | |

| Cutting and bending. On the inside of the intended fold, cuts are made to ¾ of the thickness of the sheet. After this, the workpiece bends. To fix the radius, glue is poured into the cavity of the cuts and a strip of veneer is glued over the cuts. This method is preferred for materials with a thickness of more than 25 mm. |

How to make chair covers

Fabric pad with foam filling and ribbon ties

Properly assembled furniture looks good in itself, but soft pads will make it more comfortable. The simplest option is to make pads in the shape of the seat and back with ribbon ties. You can sew such overlays yourself, or you can buy them ready-made.

DIY collapsible chair

The seat with hooks is inserted into the slot of the oval sidewall

The second side panel is put on on the opposite side of the seat

The backrest is inserted into the grooves on the sides from above

The seat is pushed with a tenon into the groove on the back and a homemade chair with round sides is ready