A miter saw is a unique tool, but only in experienced hands. The scope of application of this power tool, capable of very accurately and evenly cutting workpieces at almost any angle and inclination, is quite wide. However, most often such a saw is used during carpentry and finishing work, as well as in the manufacture of furniture. Therefore, such a useful unit should be in the arsenal of any master, since even beginners will not experience any particular difficulties while working with a miter saw if they read this article to learn the basic intricacies of operating this unique power tool and strictly follow safety rules.

How to start

It would seem, what’s so complicated here? You simply connect the unit to the network and press the “trigger” to cut the next workpiece. However, this is not at all true. Manufacturers are well aware that this powerful power tool can cause serious injury to a worker in an instant. Therefore, when you press the trigger, the miter saw starts in idle mode, and it will start cutting after the lock in the form of a special lever on the body is removed, the cutting disc drops down and touches the workpiece.

Attention!!! When purchasing a tool, do not skimp on the size of the disc, as the depth and speed of the cut will depend on this.

We make a wood milling machine for a home workshop

Milling machines are necessary for working with shaped wood parts. They are used for flat milling and profile processing. Professional equipment is multifunctional and costs a lot of money, so more and more “homemade” people are assembling such equipment for workshops and garages on their own.

Small DIY milling machine

The set of homemade wood milling machines includes:

- Drive mechanism. This is an engine whose power ranges from 1-2 kW. With such a motor, you can use various tools to work with wood without fear of failure.

- Lift for adjustment. Typically, it includes a body, sliding skids, carriages, a fixing screw and a threaded axle. During operation, the carriage moves up and down, and a screw is needed to fix it at the required level.

- Support. The table is made from solid wood.

Before assembly, be sure to draw up a detailed drawing with all dimensions. For manual wood milling machines, you need to think through everything in advance down to the smallest detail.

3D model of a table for a manual machine Equipment components Dimensions of the working element Cutting on a milling machine

The sequence of self-assembly of a convenient and practical wood milling machine for a home workshop is described in the video instructions:

If you are thinking about buying your own equipment rather than assembling it yourself, then to understand how much a manual wood router costs, look at the table with models and prices:

| Model name | Specifications | |

| Milling table Kraton MT-20-01 | site size | 64 by 36 cm |

| possibility of vertical work | There is | |

| equipment weight | 15.7 kg | |

| Milling table Kraton MT-20-01 | ||

| Milling machine Corvette-83 90830 | engine power | 750 W |

| transmission type | belt | |

| spindle speed | 11,000 rpm | |

| vertical stroke | 2.2 cm | |

| spindle diameter | 12.7mm | |

| Milling machine Corvette-83 90830 |

Making a CNC milling machine with your own hands

You can make your own numerical control equipment with your own hands. To do this, select suitable drawings of a CNC wood milling machine. You will need to assemble the model with your own hands strictly according to them.

Ready-made machine for a home workshop Equipment components Detailed assembly diagram Model of multifunctional equipment

Wood milling machines must have great strength, so it is better to take a rectangular beam mounted on guides as a basis. The lifespan of home equipment and its performance depend on proper assembly. Watch the video instructions for making such a device:

Below are photos of finished models of CNC woodworking machines with your own hands from professional “homemade” ones:

Milling cutters for woodworking machines: features and varieties

The cutter must withstand high rotation speeds during operation. Only in this case will holes of the desired shape be obtained. All options are divided into several subgroups:

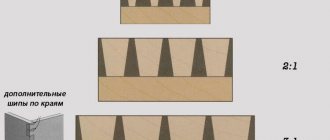

Cone-shaped. Used to process various types of wood at different angles.

Examples of various cutters

- Profile. Used to decorate elements.

- V-shaped. You can make holes at 45⁰.

- Rectangular - for creating grooves.

- Disk. Grooves of different sizes are cut out.

- Moulders for rounding edges.

- Rebated for working with quarters.

Below are photographic examples of cutters for CNC machines for wood, which are similar in principle to conventional ones, but have a “tail”:

Wood cutters

How to cut

The correct method of cutting workpieces will avoid chipping. Therefore, before starting work, experienced craftsmen wrap the part in two or three layers with masking tape or glue a piece of reinforced tape to the insert, and screw a piece of hard plywood to the parallel stop at a right angle to the table and make a control cut. Both methods work quite well, but in the second case the cut is almost perfect.

Everything else is indecently simple:

- press the trigger mechanism;

- remove the lock;

- lower the disk down.

Advice!!! It will be much safer to work with a miter saw if the tool has an automatic locking system if the saw blade suddenly stops.

How to fix the workpiece

When cutting at right angles, experienced craftsmen hold the workpieces with their free hand. However, beginners are recommended to fix the workpiece using an additional block clamped with a clamp (usually included with the power tool).

At the same time, the miter saw is capable of cutting wood, laminate, polymers and other materials at any angle, and in this case the fixing technology changes slightly:

- When turning the platform, the workpiece must be secured using a clamp. After all, the length of the cut and the applied force in this case increases, which means that it will be very difficult to hold the workpiece with your hand.

- When the angle of inclination of the saw blade changes, the workpiece is fixed slightly differently. The fact is that in this case the clamp has to be moved a little to the side, since it interferes with the tilt of the disk. Therefore, experienced craftsmen press the workpiece with a small block, which is secured with the same clamp.

There are other ways to fix workpieces, but for beginners who have not yet learned how to use a trim, for example, for beautiful processing of corners, they will not be needed yet.

How to cut at an angle

The design of the miter saw allows you to cut workpieces at any angle and inclination. This can be done by rotating the platform:

- set the required angle on the platform and fix it using a special handle;

- securely fix the part using a clamp;

- turn on the unit and release the disk down.

The second method involves changing the vertical angle of the disk:

- loosen the lock;

- move the clamp;

- select the desired angle on the disk tilt scale;

- clamp the latch;

- we fix the workpiece in a clamp;

- turn on the tool and get to work.

Note!!! The results of a miter saw will not be satisfactory if the tool has not been adjusted. More information about this operation can be found in the operating instructions or on the Internet.

We hope that these simple tips will help beginners quickly get used to using a miter saw.

Popular miter saw manufacturers

Despite the wide variety of cross-cutting machines presented, among them we can highlight the products of manufacturers that are most popular among consumers. We are talking about companies such as Bosch, Metabo, Hitachi, DeWalt and Makita. In addition to them, many interesting solutions can be found in the line.

Professional unit Makita LS 1040

Many owners of this cutting machine call it a very effective tool for making precise and clean cuts. Among the distinctive features, high power levels (1650 W) and speed, which is 4600 rpm, should be highlighted. Woodworking equipment meets all safety standards, which is greatly facilitated by the presence of a protective casing made of transparent plastic.

As follows from the reviews, many owners have been using such trimmers for many years and do not complain about a decrease in their quality characteristics. This model is also suitable for those who are looking for a mobile version of a woodworking tool, because it is small in size and weighs no more than 11 kg.

The model is designed to work with a disk with a diameter of 26 cm. This is the ideal value for the consumable to effectively trim flat workpieces with a width of 13 cm. When using the tool at an angle of 45 degrees, you can make cuts up to 67 mm deep, and when using a straight line - 95 mm. Many users note the high level of quality of the working components of this saw model. The unit is equipped with a broaching mechanism, which was positively noted by users who are forced to work with wide wooden workpieces.

Features of trims from various manufacturers

One of the features of the miter saws produced by Makita is the small cutting width . All models are supplied with a broaching mechanism. These trimmers are equipped with two special rods to securely hold the block. One of the popular models, LS 0714, has exactly this design. LF 1000 saws are ideal for processing large parts; they come with auxiliary supports that greatly simplify the operation process.

The Bosch product range also includes many models of miter saws with broaching for wood, equipped with auxiliary supports and frames, which are made of aluminum and magnesium alloys. Many owners find this solution to be correct, as it increases the strength and mobility of the crosscuts. One of the manufacturer’s popular models is the GCM 10 cross-cutting machine, the operating weight of which is 15 kg.

Sawing devices produced by the Corvette company are equipped with a special mechanism for longitudinal broaching. Among other structural elements there is a special laser pointer. Users praised this innovation, which increases the accuracy of cuts.

What differentiates Dewalt's solutions from its competitors is its XPS system. A similar mechanism can also be found in the crosscut saws from the Corvette company, but the device introduced by Dewalt has an offset function with a shadow that is projected from the saw blade. Many consumers call this system very convenient due to increased cutting accuracy.

Products manufactured by Hitachi are equipped with working blades that are ideal for making cuts at an angle of 30 and 15 degrees. Previously, no one had produced such trimmers on the market, since all previously offered devices could only work at a standard angle of 45 degrees.

Cutting saws from Metabo have rotating and tilting saw blades. Consumers are generally satisfied with the trimmers produced, calling them easy to use.

Where are Japanese trimmers made?

The line of pruning saws from this manufacturer includes about 450 different types of devices. They are produced by 8 enterprises. Enterprises located in Germany, Great Britain and Romania are involved in the production of trims. There is one plant in each of these countries. There are also 5 additional factories located in Japan.