Recently, energy resources are considered to be of great value, so people are trying to find alternative energy sources everywhere.

Recycled sawdust, leaves, or other agricultural waste can make excellent fuel. But in order to turn them from garbage into useful material, it is necessary to use a special installation - a briquette press.

Recycled sawdust has recently become more and more popular as an alternative energy source.

general information

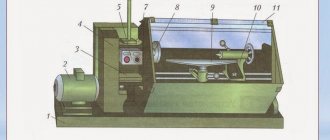

A press for the production of briquettes consists of several units and mechanisms.

These include the following parts:

- The table (base) to which the remaining components are attached, including the matrix that forms the future fuel.

- Power frame fixed to the base. Its task is to transfer force through the punch to the material.

- Mechanical or manual drive. In the first case, a hydraulic booster or electric motor is considered, and in the second, muscle power or an additional jack are considered.

Before you start using the press, you need to understand the principle of its operation and areas of application.

The advantages of the power structure are obvious:

- It allows you to create inexpensive raw materials with good energy value and high density.

- With its help, you can provide yourself with affordable fuel for heating your room throughout the cold season. For homeowners located far from gas mains, or people who want to save money on heating, this solution is completely justified.

This is what industrially pressed wood into briquettes looks like

However, it is recommended to manufacture the mechanism in the presence of a solid fuel boiler or stove, as well as in the availability of raw materials. The efficiency of the equipment and its benefits for private households depend on these two factors.

Manufacturing approaches

Before you start making fuel yourself, you need to understand what its production at the plant is based on

It doesn’t matter in what conditions the raw materials are made, at home or industrial: the preparatory stage is the same. It consists of grinding raw materials and drying them

The material used is large waste from the wood processing industry and sawdust. Sometimes agro-industrial waste is used, for example, seed husks or coal dust. The humidity of the raw materials after drying should not exceed 8%.

The next manufacturing stage is sawdust briquetting or pressing. There are 2 ways to carry out this process:

- Making briquettes using a hydraulic press.

- Extrusion method.

Whatever technology is chosen, the desired result is achieved thanks to strong pressure on the raw materials. During the pressing process, lignin, a natural component, begins to be released from it. It is he who prevents the material from crumbling. When working on a hydraulic press, sawdust is well formed into bricks. This is facilitated by random heating of sawdust.

The principle of the extrusion method resembles the operation of a juicer or meat grinder. First, the material is sent to a special bunker. It is transferred to the working channel of the unit using a screw. This is where the compression and pressing begins under a force of 1000 bar. As a result, the machine produces briquetted sawdust firewood. They are shaped like a hexagon. Briquettes undergo additional heat treatment.

Pros and cons

The main advantage of such installations is the low cost of the briquettes, which are used as fuel. With the help of such products you can heat a woodworking shop or set up autonomous heating for a greenhouse. Processed plant waste is capable of generating an impressive amount of thermal energy, providing worthy competition for many types of fuel. As a result, the manufacture of presses is becoming increasingly relevant and in demand.

Another advantage of fuel created using such equipment is its low ash content. As a result of the combustion of briquettes, organic ash appears without harmful impurities and additives, so it is often used as a fertilizer for the soil.

The automatic system with vertical design for the production of fuel briquettes is a compact automatic unit of continuous operation

The disadvantages include the high hygroscopicity of the final product , so it must be stored in special conditions where there is no moisture. The strength of compressed waste is inferior to other solid fuels, which leads to the formation of dust during the operation of briquettes. This dust often causes an allergic reaction in consumers, and if it accumulates in large volumes, it leads to the creation of an explosive and fire-hazardous mixture.

Among the key types of industrial equipment are:

- automatic systems;

- semi-automatic installations;

- models for small-scale production.

Installations can be hydraulic, pneumatic or screw. There are also models with vertical or horizontal design.

How to make a press for fuel briquettes with your own hands:

Types of briquetting machines

When thinking about which press for making briquettes will be the best for working at home, it doesn’t hurt to familiarize yourself with the design and operating features of today’s most popular models of installations so that you can choose the best option. This list includes:

- A hydraulic machine, which is the most budget and affordable of all existing presses. The low price of such equipment is due to the fact that the fuel packages produced with its help are too loose and often disintegrate into small fractions during the combustion process, not producing strong and lasting heat.

- Screw press for sawdust. Making a structure of this type with your own hands is not so easy, since it has a fairly high level of complexity in manufacturing and involves the use of certain elements such as a screw, which resembles a steel spiral rod in conventional meat grinders. Nevertheless, all the efforts made will certainly be worth it, since briquettes made on screw-type installations have a high density and the ability to burn for a long time.

- A mechanical impact press is one of the most common types of design for homemade briquette production, as it is not too difficult to manufacture. As for the finished product, the output is something between fuel packages made on a hydraulic and auger installation.

- Press granulator, which is used for processing animal feed. Such a machine is also perfect for pressing fuel raw materials, but on the condition that only its fine fraction will be processed.

When organizing a home production of briquettes for heating, you should take into account its potential power, the volume and characteristics of the available materials that will be processed by the press, as well as the availability of available tools for constructing a home-made installation. A detailed study of the pros and cons of different types of installations will also help you make the right decision.

Advantages and disadvantages of models

Most often, households and small production shops use hydraulic presses, which can operate from an individual or a common (group) drive. As a rule, such devices have the following advantages and disadvantages:

- Almost any construction waste can be used for processing in a hydraulic press, including wood, wood shavings and sawdust, plywood residues, dry leaves, etc.

- Compared with other processing units, the hydraulic press has the lowest noise level during operation.

- The high strength and reliability of the design contributes to the most accurate supply of raw materials and almost instantaneous processing, despite the fact that some units boast the presence of a speed regulator.

- The only drawback of such equipment is the low density of the briquettes produced.

That is, a hydraulic press is more suitable for those people who are simultaneously involved in the woodworking industry and do not suffer from a lack of raw materials. If there is not so much material for making fuel briquettes, then it is better to take a closer look at any other design that will allow you to produce denser briquettes that can burn for a long time and well.

An alternative to a hydraulic press can be a screw installation, which not only crushes the material into dust, drying it at the same time, but also ensures its maximum density at the outlet due to the strong pressure created inside the unit. It is worth highlighting the following pros and cons of the screw machine:

- The device boasts the highest efficiency compared to any other analogues.

- Processing raw materials in screw installations allows us to obtain the highest quality briquettes of an ideal shape with a characteristic cavity inside, which perfectly withstand transportation over long distances and do not crumble during the combustion process.

- One of the disadvantages of such a press is the need to maintain certain operating conditions to ensure a full-fledged work process. For example, a drop in the internal temperature inside a unit can quickly stop a production cycle.

- The cost of such equipment is usually very high, so many owners have to look at more budget-friendly and less productive units.

Making a screw machine will only be possible for experienced craftsmen who know how to use a lathe. In addition, to construct this complex device you will need only the strongest and highest quality steel.

The best option may be an impact mechanical machine, which, in addition to sawdust, is capable of processing straw, stone and wood, coal dust, dried flowers and any other raw materials of various shapes and sizes. The productivity of such equipment significantly exceeds those demonstrated by a hydraulic press, but is inferior to a screw machine.

In this case, the processing process can be automated as much as possible and not be given as much attention as servicing a screw-type unit requires. At the same time, the cost of such machines is too high, so many craftsmen make such structures on their own. As for granulators, they are most often used for processing the smallest raw materials, although some craftsmen use similar installations for double processing, first crushing the raw materials and only then proceeding to compact them into fuel packages.

Briquette production technology

Understanding how to make a briquette press yourself is relatively simple. To do this, you need to adhere to general recommendations and follow the step-by-step guide.

The task of such a mechanism is to grind the feedstock, which is usually used as waste from woodworking enterprises, as well as its further drying. To make fuel from wood waste, its moisture content must be brought to 8-10%. In addition to plant components, coal dust is also used to produce briquettes.

After preparing the necessary components, you can proceed directly to the production of briquettes using one of two technologies:

- Pressing. In this case, the raw material must be placed in a special form, called a matrix, and crushed using a powerful hydraulic press. The part that acts on the raw material is called a punch. The machine itself is capable of developing pressure up to 300-600 atmospheres.

- Extrusion. According to the principle of operation, a professional extruder resembles a screw meat grinder. The feedstock passes through a narrowing channel, and the pressure that affects it is about 1000 atmospheres.

Technology for producing briquettes on an industrial scale through pressing.

With strong compression, the prepared mass is heated to high temperatures. Sticky substances are released from small particles of material, which begin to bind the mass and make it solid. The density of raw materials reaches 900-1100 kg/1 m³. For comparison, for high-quality wood they are 500-550 kg/1 m³. The processed mass acquires a high thermal potential, and its energy value doubles.

Such briquettes burn several times longer than ordinary wood. As a result, they go through a heat treatment stage, they are cut into equal parts and delivered to the warehouse.

Faced with the issue of producing fuel from waste, many people have a dilemma between buying factory equipment and making a press for fuel briquettes with their own hands according to drawings.

How to make briquettes yourself?

It is problematic to use fine-grained wood waste (tyrasa, sawdust) as fuel in its “natural” form - due to its low density, it quickly burns out, releasing a small amount of heat, and is poured from the grate into the ash pan, which increases consumption.

If you have free access to an unlimited amount of sawdust and a desire to make it suitable for burning in a stove or heating boiler, you can make sawdust briquettes with your own hands.

What you should immediately pay attention to

- Only expensive industrial equipment can compress raw materials until lignin is released; for handicraft production, a binder will have to be added to the raw material;

- The formed briquettes must be dried in air and stored somewhere, i.e., it is necessary to take care of a suitable spacious room, a canopy in case of bad weather.

To make briquettes from sawdust, you will need the following equipment

- grinder (the finer the fraction of raw materials, the higher the density of the final product), you can use a device that grinds plant materials to prepare compost;

- manual or hydraulic press + suitable containers for molding;

- a container for manually mixing raw materials, a construction mixer or a compact electric concrete mixer.

Features of briquetting

The production of fuel briquettes from sawdust begins with the preparation of raw materials. The sawdust is crushed (if possible) and soaked in water.

Then the binder is added

- clay (an affordable and cheap option, added in a ratio of 1:10, but after such briquettes a large amount of ash remains, since clay does not burn);

- wallpaper glue (increases production costs);

- crushed soaked cardboard, waste paper (proportion 1:10, the additive is safe, burns almost completely, but during production it will be necessary to increase the time for drying the formed briquettes).

After mixing manually or mechanically, the raw materials are placed in a mold for sawdust briquetting. This is a rectangular or cylindrical metal container with a perforated bottom and walls. Small diameter holes are needed to drain excess moisture during pressing.

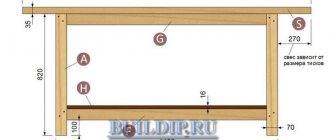

A homemade briquette press can be floor or wall mounted. It consists of a powerful steel frame welded from a profile and a working part. The rod moves by twisting or by pressing on the lever. A manual press with a screw rod squeezes better, but it takes a lot of time to make one briquette. A self-made press with a lever can be equipped with two rods to increase productivity.

You can see the design of the described machine in this video:

Squeezing moisture out of briquettes using muscular effort is difficult and ineffective. The blanks have to be dried for a long time; when finished, they crumble easily and burn quickly due to their low density. To improve product quality, the press for making homemade briquettes is equipped with a hydraulic car jack, securing it upside down on the top beam of the frame. The hydraulic force depends on the characteristics of the jack.

Sawdust fuel briquettes, removed from the mold, are laid out to dry in the sun or in a well-heated room. You should achieve a humidity level comparable to at least that of wet firewood (up to 25%). The drier the fuel, the higher its heat transfer. Solid fuel and pyrolysis boilers are designed to use fuel whose humidity does not exceed 30%.

Advantages of homemade structures

The cost of an industrial press for making briquettes ranges from 300 thousand to 1 million rubles. Few people are willing to shell out that amount of money, so making your own machine is becoming increasingly important. And it is not advisable to buy such an expensive mechanism for your own household needs, since its return on investment is very low.

As for homemade presses, it is quite possible to make them at home. In this case, you can try to build the system from scratch or purchase several units for assembly.

According to the scheme, it is quite possible to make a homemade press machine at home

When considering the option of manufacturing from scratch, you need to acquire the following compression mechanisms:

- With a lever.

- Screw mechanism.

The first device is characterized by a simple design, and it can be made from ordinary wood. As for screw mechanisms, they imply the presence of steel blanks and a lathe. A screw extruder, which is more complex in terms of production, is also created by hand, but for this purpose you have to buy expensive, high-class steel.

Heating a room with briquettes made from vegetable waste is not only cheap, but also environmentally friendly. This is explained by the absence of harmful additives and impurities in the fuel. To install a heating system, you can use a homemade pellet boiler or slightly modernize a ready-made solid fuel installation.

Benefits of sawdust logs

The following arguments can be given in favor of briquettes pressed from sawdust:

- Long burning time - 4 hours.

- Minimal smoke generation.

- Environmentally friendly. The starting materials are natural materials, so you can fertilize the beds with ash.

- High energy output. It far exceeds the energy capabilities of firewood and is comparable only to high-quality coal.

- Constant combustion temperature.

- Economical. The cost of 1 ton of such fuel will be cheaper than the corresponding amount of firewood or coal.

- Possibility of self-production.

There are also disadvantages. The main one is the fear of moisture. They cannot be stored in the open air, because... they will quickly absorb moisture and therefore will burn poorly. Therefore, it is necessary to allocate a dry room for storage.

Any significant mechanical impact on sawdust briquettes is contraindicated. If you buy special equipment for their production, the cost will be high and not always justified.

Replacing coal and firewood with sawdust briquettes makes heating a country home more environmentally friendly. While heating with wet wood leads to the release of harmful substances, “Eurowood” is completely safe in this regard

It is profitable to set up handicraft production if the sawdust is free, and you can use existing equipment for installation.

Manufacturing based on other devices

If there is no desire to create a press for making briquettes from scratch, then you can try to rework some other device for such a mechanism. This can be a jack or a small hydraulic press, which is additionally equipped with a punch and a die.

It is important to understand that all home-made installations are not capable of providing the pressure at which lignin production occurs. As a result, a number of third-party additives are added to the original mass, including:

- inexpensive adhesive (for example, for wallpaper);

- clay (for 1 part of raw materials take 10 parts of waste);

- soggy paper or corrugated cardboard.

When producing a machine for briquettes, it is important to take into account such a stage as grinding raw materials. Manual cutting of the material is not recommended, since such manipulation takes a lot of time and effort. Instead, it is recommended to use additional devices, for example, a shredder from an old activator washing machine, into which knives are placed. You can also buy a rotary machine. Its task is to grind plant components.

Another important point is the grinding of raw materials; manual cutting of the material is not recommended, since such manipulation takes a lot of time and effort.

To successfully manufacture a lever or screw press, you do not need to purchase additional parts. However, such devices do not have special operating properties. A press made from a hydraulic jack, on which an electric or manual drive is installed, will be more effective.

A punch is added to the finished equipment, the dimensions of which are comparable to the dimensions of the matrix where the pressing takes place. To create the matrix, take a thick-walled pipe in which holes are made for the ventilation system. The matrix is additionally equipped with a removable bottom - it can be removed after receiving the finished briquette.

Design features of the pressing apparatus

A homemade briquette press is a mechanical unit. Its key elements:

- Work table-bed. All structural parts of the press will be fixed on this basis.

- Support frame. Regulates and directs the force that a person exerts on the press.

- Drive unit. Can be manual or mechanical (hydraulic or electric motor).

- Punch. This is a drive element that has a direct impact on the bulk raw material.

- Forming container. Must have perforations.

The simplest press is equipped with a screw manual drive. Pressure is applied to the workpiece by tightening the screw. Its productivity is quite low, so this press has not gained wide popularity among the people. Time and energy are wasted on loading and unloading and tightening the screw. A briquette press with a long lever and the function of independently squeezing the finished brick outward looks comparatively more advanced. Such a machine can be improved by complicating the design with a hydraulic jack.

Advice. To speed up the pressing process, a second matrix mold is welded onto the work table.

Materials and available tools

To make a briquette press with your own hands, you need to stock up on some materials and available tools. In addition to the main component, you will also have to buy different types of rolled steel:

- channel;

- corner measuring 100x100 mm;

- a sheet 3-6 mm thick from which you will need to cut a punch. The thickness of the workpiece is determined by the diameter of the matrix.

It is also necessary to prepare a pipe with a cross-section of 25-30 mm for the manufacture of the punch rod, a thick-walled pipe for the matrix and a larger one for the body. In the absence of such material, the drum can be created from a sheet of tin. Also, galvanized steel is prepared for the upcoming work - trays are created from it.

The machine is assembled according to the following instructions:

- Equip the base of the device. It is created from channels using a welding machine.

- Based on the angle, four 1.5 m long posts are made. They are welded vertically with the same pitch.

- Next, a drum is created from a steel pipe or sheet of tin, where the feedstock will be mixed. If you have a broken washing machine in your house, you can remove the drum from it.

- The drum structure is then welded to the racks. If possible, it is better to equip it with an engine. If the power plant creates strong vibrations during operation and its rotation speed is too high, this can be solved using a gearbox.

- A tray is installed under the drum through which the raw materials will be fed into the matrix.

- At the bottom of the matrix there is a flange to which a removable bottom is screwed. It will require a steel sheet.

- Then you need to weld or screw the matrix to the base.

- A round punch is cut from a sheet of steel. Instead, you can use a regular disk of suitable diameter.

The briquetting press is designed for the production of fuel briquettes from soft and hard wood sawdust, sunflower husks and other plant waste

Useful tips

Although using a homemade press it is unlikely that it will be possible to produce a high-density briquette, it is quite enough for heating rooms in the cold season. The installation solves the main problem with a bang - the crumbly loose raw material becomes a solid brick or a cylindrical mass, which is then placed in a solid fuel boiler.

In order for the creation of a hydraulic press for the production of fuel briquettes to be justified, you need to take into account a lot of factors. First of all, it is important to make sure that the raw materials are available and cheap. You should also evaluate the weighted average volume of material received, the type of waste used and your own need for solid fuel. If heating with briquettes allows you to significantly save money, then making a press is a good solution with a long-term perspective.

Making a box

For this we need a metal profile pipe measuring 140x100 mm. Cut a piece 20 cm long.

Holes must be drilled in the box to drain water. Or you can simply make vertical slits with a grinder.

1

Types of fuel briquettes

Briquettes are divided into types depending on their shape. Mainly the following types can be found on the market:

- RUF. These are pressed rectangles measuring 15 x 9.5 x 6.5 cm. They are made from natural wood sawdust with the addition of special components.

- Nestro. Visually, these are cylinders with a diameter of 6 to 9 cm and a length of 5 to 35 cm, without holes. The material for production is pressed wood pulp. It is dried, placed in a loading container, and then fed through a screw for pressing. Dispensers distribute the mass into molds under pressure.

- Pini kay. In shape they are polyhedra with the number of faces from 4 to 6. During the production process they are subjected to processing at high temperatures and pressing under high pressure, up to 1100 bar. As a result, combustion efficiency, moisture resistance, and density increase.

The chemical composition and heat transfer of all these types of pressed sawdust are the same, they differ only in density. This fuel is not characterized by sparks flying in different directions. Its high density and low hygroscopicity make it possible to store this fuel in a small pantry next to the stove.

In addition to sawdust, sunflower husks, buckwheat, paper, small branches, fallen leaves, and straw are used to produce briquettes. The equipment for this has a fairly simple design, and you can make it yourself

If you have the necessary raw materials to form briquettes, you can make them yourself.

Ready-made equipment for home production

The production of fuel briquettes requires special equipment.

Therefore, in order to create high-quality products with your own hands, you need to purchase:

- Grinding device.

- Drying machine.

- Press.

But it is not practical to buy expensive machines for briquetting wood waste at home.

It makes sense to use powerful installations only when producing fuel briquettes in large volumes.

You can make briquettes as a material for heating a private home without a dryer. It is easy to remove moisture from prepared raw materials in a natural way. To do this, sawdust or wood shavings are laid out in a small layer on the street under a canopy.

A homemade press is often used to create compact fuel. Such a device will not provide a high compression density of the material, but will still make it possible to make fuel suitable for home use.

Species diversity

There are several types of presses:

- hydraulic;

- screw;

- shock-mechanical;

- granulators.

The differences lie in the method of creating pressure and the characteristics of the briquettes.

Hydraulic

Machines of this type have the following characteristics:

- The production method is intermittent.

- The working mechanism is hydraulic: force is created by pumping oil into the cavity of the hydraulic cylinder.

- Specific pressure – 500–1500 kg/sq.cm.

The hydraulic machine has an intermittent production method.

Raw materials are loaded in portions into a mold (glass). After compression, the finished briquette is removed.

Hydraulic presses have 2 advantages:

- low cost;

- briquettes are shaped like bricks (RUF), which makes transportation and storage easier.

Flaws:

- low productivity;

- relatively low pressure - the density of the bars does not exceed 0.75–0.8 kg/cc.

Screw

Press characteristics:

- The manufacturing method is continuous.

- The working body is a rotating auger (like in a kitchen meat grinder).

- Specific pressure – up to 3000 kg/sq.cm.

The press operates on the principle of extrusion: a screw forces the mixture through a gradually narrowing hole - a die. Due to the conical shape of the channel, the compression force from its walls is several times higher than the pressure developed by the screw. A similar effect is observed when driving a wedge into a crack, which leads to the splitting of a tree trunk.

A screw press forces the mixture through a tapering hole.

Installation benefits:

- High density of briquettes – 1.08–1.40 kg/cc. This fuel burns for a long time and produces a lot of heat.

- High performance. Thanks to the continuous operation of the extruder, it is possible to produce more briquettes per unit of time than with a hydraulic installation.

- The log has a Pini&Kay format - with a hexagonal cross-section and a through hole in the middle. The channel ensures the flow of air to the internal layers and, as a result, the most complete combustion and minimum ash content.

The disadvantage of a screw press is its high cost.

Impact-mechanical

Equipment characteristics:

- The production method is continuous.

- The working body is a rotating crankshaft with a connecting rod attached to it (crank mechanism).

- Specific pressure – up to 2500 kg/sq.cm.

There is another type of extruder, when the raw material is forced through a die by a piston moving back and forth.

In terms of cost and productivity, mechanical impact presses occupy a middle position between hydraulic and screw models. The same can be said about the density of the bar: it is 1–1.15 kg/cc. It has a round cross-section (Nestro type) with a through hole.

The mechanical impact press operates continuously.

The disadvantage of the equipment is accelerated wear of the bearing due to impact.

Despite this, such presses have become widespread due to the optimal combination of installation price and product quality.

Press granulator

This is a universal extruder for the production of fine-grained pressed products. If the raw material is crushed grain, the output is compound feed; if sawdust, peat, seed husks, etc. - fuel granules (pellets). The advantage of small-caliber briquettes is the possibility of automatically feeding them into the combustion chamber of the boiler using a screw or piston feeder. The heat generator must be equipped with a special pellet burner.

Press selection criteria: what to look for

When choosing a machine, consider the following:

- Electric motor power. It is limited by the capacity of the circuit breaker at the entrance to the house and the cross-section of the cables. The most energy-intensive are screw units.

- Distance to the supplier's service department. The closer it is located, the faster the repairs will be completed and the less losses there will be from equipment downtime.

- Telephone consultation. A useful service from a supplier or dealer can help you avoid mistakes and save money.

- Volume of available raw materials and market capacity. The costs of purchasing a machine with excessive productivity will be unreasonably high, and along with them the cost of repairs. These factors will increase the payback period of the equipment and lead to a decrease in production profits.

When choosing a machine, consider the power of the electric motor.

Is it worth making briquettes at home?

In real life, sawdust fuel briquettes made by yourself do not turn out quite the way they are presented by some online resources. This casts doubt on the feasibility of the entire enterprise, and here’s why:

- On colorful videos from the Internet, the process looks simple and easy. In reality, this is hard work; in order to prepare the required amount of fuel for the season, you need to spend a lot of time and physical effort;

- The heat released by homemade briquettes during combustion is much lower than that of factory-made products. The whole point is the insufficient density of the “bricks”, since home appliances cannot provide the required pressing pressure;

- drying in the sun cannot be compared with industrial dryers, so the fuel contains moisture, which affects the calorific value;

- homemade sawdust fuel contains clay, which is not burned in the boiler firebox. This means there will be more ash left.

Eurowood production process

First of all, it is necessary to understand industrial technology in order to further adhere to its principles.

First, sawdust, shavings, and larger wood waste are crushed. Then the raw materials are thoroughly dried until the humidity level is reduced by 90%. In addition to heating, they may include waste from the agricultural industry: grain husks, seed husks. If the briquetted sample consists of coal dust, it is better not to use it in everyday life.

After grinding and drying, the main production stage occurs - sawdust pressing. For this purpose, a briquetting press or an extruder is used, depending on the chosen method of forming the fuel. Extrusion and pressing - intensive compression of the raw material in order to obtain the binder lignin (a natural component extracted from wood). It replaces adhesives and preserves the environmental purity of fuel. With the first compression method, the hydraulic briquetting press develops a force of about 500 bar. Because of this, spontaneous heating of the raw materials occurs, the sawdust is knocked together into a dense rectangular brick.

Extrusion production technology is similar to the operation of a meat grinder. The source material enters the loading hopper and is pushed into a narrowed conical channel using a screw. A screw press for the production of fuel briquettes produces a force of 800–1000 bar. The result is a hexagonal briquette, additionally processed at high temperatures, cut into segments of equal caliber. The drawing shows the design of the screw unit in section.

Briquetting at home

Buying a press for the production of fuel briquettes is not entirely reasonable, even if you have available raw materials: the purchase is unlikely to pay off unless you start selling the finished product. Without a professional unit, it is impossible to withstand industrial technology and obtain lignin, which serves as a binding element. But there is a way to use wood waste by introducing various binding ingredients into the sawdust composition:

- wallpaper glue,

- clay,

- paper.

In order not to purchase professional equipment for drying and pressing chips, more affordable technology is used. Wood waste is soaked in water and combined with clay in a ratio of 1:10. Instead of clay, add soaked cardboard or wallpaper glue.

After mixing, the resulting mass is placed in the mold of a homemade machine for producing briquettes and squeezed tightly with your hands. The bricks are taken out and sent to dry.

Homemade device

The design of the sawdust press includes a mechanical screw drive. A perforated container installed on the briquetter, after filling with the prepared mixture, is placed under the frame. The screw is tightened by hand and pressure is created. It’s not difficult to make a device; you don’t need a diagram or drawings, just look at the drawing.

The screw device has low productivity. Working with it requires a lot of time loading the mold and tightening the screw. It is not very convenient to remove the briquette from the mold. An alternative is a homemade press, which includes a lever element and a special ejector for extracting the finished material. To optimize the production process, the frame is often equipped with not one, but two forms.

There is also a more advanced type of mechanized equipment. A home mini-press can be equipped with a hydraulic jack rather than a manual one, which can significantly increase fuel production. This briquetting machine requires some skill to assemble. But you should not count on providing the pressure necessary to squeeze out the lignin. It will not be possible to do without additional connecting components.

Methods for creating a device

It is impossible to make an extruder at home. All homemade machines press briquettes into a mold (glass) in an intermittent manner.

The main task of the designer is to ensure a specific pressure of at least 150 kg/sq.cm. This value is determined by 2 factors:

- force generated by the press (direct relationship);

- cross-sectional area of the mold (reverse).

By selecting the ratio of these parameters, the desired characteristics are achieved.

For example, a machine presses on a portion of raw materials with a force of 1350 kgf. If the block has a cross-section of 5x5 cm, the specific pressure will be:

P = 1350 / (5 x 5) = 54 kgf/sq.cm

At such low rates, the briquette will crumble. By reducing the dimensions of its cross-section to 3x3 cm, the designer will increase the specific pressure to:

P1 = 1350 / (3 x 3) = 150 kgf/sq.cm

There are several ways to achieve high force.

The designer's task is to ensure the specific pressure of the press.

Use of muscular strength and leverage

This is the simplest version of the press; all its elements can be made at home.

A strong pipe is used as a lever, for example a reinforced water pipe with a diameter of 40–50 mm and a wall thickness of 4–4.5 (mm). One end of it is equipped with an axis and fixed in a bracket so that the other side can be raised and lowered.

A rod with a punch is attached at a short distance from the point of rotation.

The compression force will be equal to Q = P * (L / L1), where:

- P – operator’s weight acting on the free end of the lever;

- L – pipe length;

- L1 – distance from the point of rotation to the junction of the rod and the punch.

Example:

- operator weighs 90 kg;

- lever length – 3 m;

- the distance from the pipe rotation point to the punch is 0.3 m.

Under these conditions, the compression force will be:

Q = 90 * (3 / 0.3) = 900 kgf

It must be taken into account that the same force acts on the bracket at the point of rotation of the lever, so it must be strong.

To achieve a pressure of 150 kgf/sq.cm, the cross-sectional area of the bar must be equal to:

S = 900 / 150 = 6 sq.cm

The lever installation is designed so that briquetting is carried out in one step. Otherwise, you will have to waste time adding raw materials, which will lead to a decrease in productivity.

The immersion depth of the punch depends on the volume of the portion. It is calculated using the formula A = H * (1 – (p1 / p2)), where:

- H – height of the glass;

- p1 and p2 are the density of raw materials and briquettes, respectively.

The larger A, the further the rod needs to be moved from the point of rotation. But this leads to a decrease in compression force.

The parameters are selected as follows:

- Calculate the cross-sectional area of the pipe from which the glass will be made.

- The required force is calculated and based on this the distance of the rod to the point of rotation is determined.

- A test briquette is made.

- If in 1 approach it was not possible to achieve the required degree of compression, cut off part of the glass to reduce its length.

Formula for calculating the piston pressure force (m) depending on the force applied by a person (M), the distance from the piston to the lever attachment point (l) and its total length (L)

If high productivity is not needed, the briquette is made in several stages, adding more raw materials.

To increase the pressure on the lever, you can attract an assistant.

Application of hydraulic jack

A household hydraulic jack develops a force of 30–40 tf. If you equip a press with it, the available mold area will be:

S = 30000 / 150 = 200 sq.cm

The hydraulic jack develops a lot of force.

This machine can be equipped with several forms. Then the frame for the punches is made of durable rolled products, for example an I-beam or a thick-walled profiled pipe.

The disadvantage of a press based on a hydraulic jack is the long cycle time. But it has higher productivity, and the briquettes are more similar to those made industrially.

The design of a typical hydraulic press consists of a frame and a movable beam on which a jack is placed. The system returns to its original position due to the action of springs

Screw pressing mechanism

Another device for enhancing muscle strength is a screw. The amount of pressure it creates is calculated based on the “golden rule of mechanics”.

L1 / L2 = Q2 / Q1, where:

- L1 – path traveled by the point of application of muscular force;

- L2 – movement of the punch mounted on a screw or lever;

- Q1 – muscular strength;

- Q2 – pressure developed by the press.

Example:

- the length of the handle in the screw shank is 80 cm (2 arms of 40 cm each);

- force applied by the operator – Q1=40 kgf;

- screw thread pitch – 3 mm.

The screw pressing mechanism enhances muscle strength.

For 1 revolution, the point of application of muscular force, i.e. the end of the handle will go the following way:

L1 = 2 * P * 40 = 2 * 3.14 * 40 = 251.2 cm

The punch will drop to L2 = 3 mm = 0.3 cm. The force of its influence on the raw material is equal to:

P2 = (L1 * P1) / L2 = (251.2 * 40) / 0.3 = 33493 kgf

The actual force will be less because The operator will spend part of the energy to overcome friction in the screw-nut pair. The average efficiency of such devices is 25–30%. This means that the press considered in this example presses on a portion of raw materials with a force of 33493.3 * 0.25 = 8373.3 kgf.

Advantages of screw presses:

- the greatest strength among hand-held devices;

- compactness;

- simple design.

Flaws:

- the cycle is longer;

- The manufacture of the screw and nut will have to be ordered by a turner.

The operator must control the applied force, otherwise the thread may be stripped.

It is recommended to increase the pressure little by little and, as soon as an acceptable result is obtained, put a mark on the screw indicating the extreme position.

Homemade briquettes - pros and cons

The reasons why this type of fuel is very attractive are clear. When a person has his own wood production or the opportunity to cheaply buy sawdust for briquettes, then thoughts about making them at home are quite natural. The fact is that not every heating equipment is suitable for burning sawdust. As a rule, fine wood in a conventional stove or boiler burns quickly and gives off little heat, and even half will spill into the ash pan.

It turns out that not everything is so simple here either, and here’s why:

- Buying factory drying and pressing equipment is an unreasonably expensive undertaking. It is cheaper to purchase ready-made European firewood.

- You can make a briquette press yourself and make them in an artisanal way. But the products will be of low quality and will provide little heat, and will take a lot of time.

After squeezing out the water and subsequent drying, the briquette becomes quite light

Point two requires clarification. Due to the impossibility of following the technology, the “bricks” after drying are light due to their low density. Their specific heat of combustion is three times lower than that of wood, which means that for heating they will need three times as much. The whole process will take a lot of time and consume a lot of energy. And it is very difficult to store such a volume of fuel so that it does not accumulate moisture.

Educational video for enthusiasts who want to start manual briquetting of various household waste:

This is interesting: We make it with our own hands - a lean-to canopy made of metal profiles