Both in everyday life and in professional activities, from time to time there is a need to saw off something. These can be a variety of materials, ranging from wooden blocks to metal pipes. The relevance of the tool during construction and repair work increases many times over. Well, a professional specialist needs an impressive set of units for different types of work.

One very useful tool is a reciprocating saw. The tool received this name for the specific shape of the hacksaw blade, which really is a bit reminiscent of edged weapons, which became most widespread in the late Middle Ages and Modern times.

Types of reciprocating saws

According to the type of power supply, reciprocating saws are divided into two types:

- powered from the network;

- battery powered.

Mains-powered devices tend to be more powerful, have a longer run time, and are lighter than comparable battery-powered ones. But battery-powered ones do not require wires, and in the garden or on objects under construction or dismantling, where sockets are not available, it is much more convenient to work with them.

Reciprocating saws are also divided by area of application.

A household reciprocating saw has less power (400-600 W), and its continuous operation time is measured not in hours, like a professional one, but in minutes. They are lighter, more compact, and can be handled by a woman or a teenager. The range of options is also narrowed; cheaper materials are used. All this leads to lower prices.

Professional models have greater power (700-1500 W), longer operating time without interruption, a longer total resource, and are made of more durable and high-quality materials. They also have a wider list of additional functions. All this results in greater weight, dimensions, and a higher price.

Professionals also have their “heavyweights.” So, for working in difficult conditions, on metal and stone, choose a device with a power of 1200 W or more. In addition, there are models of the Alligator type with three blades - two working and one guide, fixed. The width of the cut increases, but the speed of work and the cleanliness of the cut surface increase significantly.

Until recently, there was a division by material - but today an electric hacksaw for wood and a reciprocating saw for metal are combined in one device.

Rating of powerful electric hacksaws

Powerful electric hacksaws are purchased by users who intend to carry out repair work with them and simply use the tool intensively. In addition to high power, the equipment is equipped with wide functionality designed to make work easier.

Einhell TE-AP 1050 E

| Specifications Power: 1050 W Revolutions: up to 2700 per minute Blade stroke: 29 mm Maximum cutting thickness of metal / wood: 20 / 200 mm Weight: 3.75 kg Quick-release mount: yes Speed adjustment: yes Pendulum stroke: yes Soft start: yes Backlight: no Average cost: 8100 rub. | |

| The model is designed for high-speed cutting and accurate cutting of fragile materials. It has a power regulator, as well as ventilation holes that cool the engine. | |

Makita JR3050T

| Specifications Power: 1010 W Revolutions: up to 2800 per minute Blade stroke: 28 mm Maximum cutting thickness of pipe / wood: 130 / 255 mm Weight: 3.2 kg Quick-release mount: yes Speed adjustment: yes Pendulum stroke: no Soft start: no Backlight: no Average cost: 9000 rub. | |

| This is a reliable reciprocating saw, with videos and photos showing that this tool is capable of cutting through metal pipe. Manufacturers equip the model with a system for quickly changing the cutting blade and a cable for operation from a power supply network 4 meters long. | |

AEG US 1300 XE

| Specifications Power: 1300 W Revolutions: up to 2800 per minute Blade stroke: 30 mm Maximum cutting thickness of metal / wood: 20 / 250 mm Weight: 3.8 kg Quick-release mount: yes Speed adjustment: yes Pendulum stroke: no Soft start: no Backlight: no Average cost: 10,500 rub. | |

| A review of reciprocating saws shows that this tool is designed for cutting workpieces made of plastic, metal, wood and other materials. For user convenience, the model has rubber pads. | |

Hitachi CR13V2

| Specifications Power: 1010 W Revolutions: up to 2800 per minute Blade stroke: 29 mm Maximum cutting thickness of metal / wood: 19 / 300 mm Weight: 3.2 kg Quick-release mount: yes Speed adjustment: yes Pendulum stroke: no Soft start: no Backlight: no Average cost: 12,000 rub. | |

| The most popular area of application is repair work on dismantling old pipes. However, it is often used on other materials. The maximum file length can be 43.5 cm, which allows you to work with large workpieces. | |

Makita JR 3060 T

| Specifications Power: 1250 W Revolutions: up to 2800 per minute Blade stroke: 32 mm Maximum cutting thickness of pipe / wood: 130 / 255 mm Weight: 4.2 kg Quick-release mount: yes Speed adjustment: yes Pendulum stroke: yes Soft start: no Backlight: no Average cost: 13,500 rub. | |

| A reliable tool with a shock-resistant body and high resistance to intense loads. The main scope of application is construction work. It is irrational to purchase this model for domestic needs. | |

article from the categoryRating

Power tools Carpentry tools (for wood) For working with metal

Save this page on your social media. network and return to it at any time.

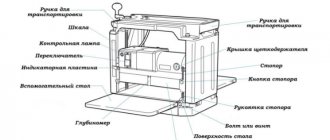

Reciprocating saw device features

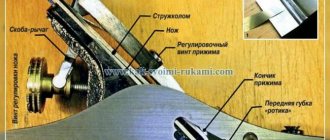

The design of a reciprocating saw resembles the reinforced design of a jigsaw. The electric motor, through a gearbox and a crank mechanism, carries out reciprocating movements of the rod in a chuck, at the end of which a cutting blade is fixed.

To speed up work and reduce blade wear, the reciprocating electric saw is equipped with a pendulum mechanism that raises the blade during the reverse stroke.

Reciprocating saw design

An important feature of the reciprocating saw is the stop shoe, the position of which can be adjusted for better support on the object being cut. The shape of the shoe allows you to confidently fix the saw on flat and curved objects.

Features and Functions

The main characteristics of the reciprocating saw are:

- Engine power.

- Rod movement frequency (usually 2500-3000 strokes per minute).

- Working stroke length (20-30 cm).

- Maximum cutting depth in mm for various materials.

Power is the parameter that determines all other capabilities. The greater the power, the greater the capabilities of the device.

It is important to understand that this will increase weight, dimensions and price.

The most important function is speed control. It is implemented in two ways:

- Smooth, carried out by the power button, depending on the depth of pressing. This method requires a certain skill.

- Stepped. Using a slider or wheel regulator on the saw body, one of the modes for limiting the maximum frequency of movement of the rod is set, and by pressing a button the frequency is adjusted within the specified limits. This method prevents the maximum speed from being exceeded when the power button is fully pressed.

Reciprocating saw for metal

Also important are the following functions of an electric reciprocating saw:

- Pendulum function.

- Blade changing mechanism. It may be called differently by different manufacturers and in different models, but the meaning should remain the same - the blade can be changed with one hand, without removing work gloves.

- Ergonomics. Both the general ease of operation and the accessibility of switches and regulators.

- Vibration isolation. An extremely important function; when cutting thick materials or metal, a saw without vibration isolation will shake so much that it will be pulled out of your hands.

There are also a number of very useful functions:

- Frequency stabilization under load.

- Overload protection - automatic shutdown of the motor when the blade jams.

- Electrodynamic brake for instant stop of the rod.

- Illumination of the working area with an LED lamp.

Manufacturers add other sometimes exotic features. Not all of them stand the test of time.

What to pay attention to

Before purchasing a tool, it is best to hold it in your hands. Of course, this cannot always be done when ordering in an online store. In this case, try to “touch” the unit with friends or in a store before ordering it online.

Close attention should be paid to the following components and parameters:

- Attaching the blade to the rod . The file should not dangle. Backlash indicates a poor-quality connection.

- Noise during operation . Excessive noise in a medium-power model indicates poor-quality assembly and fitting of parts.

- Vibrations . The larger they are, the more tired you will feel after a short period of work. An extremely useful thing is a special balancer that dampens vibrations. It greatly improves the ease of use.

- Comfortable grip . For occasional home work, almost anything will do. In a more expensive tool, pay attention not only to the handle, but also to the forend of the body. There are models in which there is also a handle, and a rotary one.

- Power cord length . To work in the garden and outside, a “carrying” will be required in any case. But it would be better not to create a tangle of wires indoors. In good units, the cord length is at least 3 m.

Application of reciprocating saws

Reciprocating saws can cut:

- Boards, plywood and solid wood, including screws, staples, and nails.

- Metal profile, rod and pipes.

- Various plastics.

- Brick, foam concrete and natural stone.

These applications of a reciprocating saw are not possible for a jigsaw or a chain saw - they will become dull or fail at the first screw. With a reciprocating saw you can cut a pipe close to the wall - its blade bends up to 30 degrees.

Unboxing and appearance

For some reason, the courier asked me to sign on a piece of paper and cut it out along with a piece of the package... but oh well.

The box was slightly damaged during delivery.

The saw itself is clean and intact. If it was in such a crumpled package in a warehouse, there would be a lot of dust inside, apparently the delivery “tried its best.”

Also included is a universal blade that is not of the worst quality, but the teeth are large and are only suitable for wood/soft metals.

There is also a hexagon for adjusting the reach of the “shoe”.

And spare brushes, size 9.8x5.8 mm.

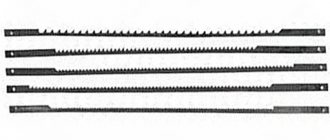

A few words about electric reciprocating saw blades

The hacksaw blade is the main working part of a reciprocating saw. Its length, width, thickness and shape vary for different applications. All of them are made of high-strength tool steel and are durable and elastic.

There is a generally accepted marking of the fabric material:

- HCS - the blade is made of high carbon steel, the teeth are large, located at an equal distance from each other. Such blades are used for cutting relatively soft materials: wood, panel materials, rubber and plastics.

- HSS—high-speed tool steel. Used for aluminum, thin-walled rolled products.

- BIM are bimetallic blades made from HSS and HCS plates. They are distinguished by high strength and high flexibility. Used for cutting mixed materials: wood or aerated concrete along with nails.

- HM/CT - carbide blades. It is used for hard materials or for highly abrasive porous materials, such as concrete structures, metal, fiberglass, tiles.

Reciprocating saw blade

Some manufacturers also use their own labeling systems.

An unsuitable blade for a particular material can result in poor quality cuts, equipment failure, or even injury. When choosing a canvas, you should pay attention to:

- Purpose - the canvas must correspond to the material;

- Teeth – for a quick cut, choose larger teeth and set apart; for quality cutting, choose small teeth with a slight set apart.

- Mounting method must be suitable for your saw.

Most blades come with a universal mount, but some manufacturers promote their own shank and chuck shape.

Well, dismemberment, where would we be without it =)

The first step is to remove the “shoe”. We unscrew the bolts with a hexagon and pull out the bar. The hardest part was removing the rubber cover from the front. It differs from the soft and pleasant insert on the handle. The material is quite hard, somewhere between hard rubber and soft plastic. These little “moustaches”

They just get stuck tightly in these grooves

Next, simply unscrew all the screws and divide the case into 2 halves. No boards, no button, no motor.

The gearbox housing is aluminum.

They obviously didn’t skimp on the lubricant - they threw it in heaps and collected it =)

I didn’t disassemble the gearbox, otherwise it would have stained the floor of the house, so here’s a photo from the internet.

Well, here's a more detailed diagram

Replacing brushes is very easy. You just have to disassemble the case.

I messed up a little - I forgot to take the dimensions of the bearing and only saw it while writing the review. My father pressed the saw right after filming the material (he asked for it for him), so I can only attach a photo with part of the markings, maybe someone will recognize it.

Bearing seats with damping pads - this is the first time I’ve seen this, maybe I just didn’t pay attention.

It seems like I haven't forgotten anything else.

I also became interested in what the gear ratio is. One maximum stroke of the piston accounts for about 5 engine revolutions. This is obtained with a maximum of 5100 vibrations and the motor rotates at a speed of about 25,000 rpm. For those who want to watch the process of cutting various materials, I made a short video selection, practice after 2:00.

I don’t describe the pros and cons in posts according to point 18, I just test the product and show you the results, draw your own conclusions =)

To receive a discount and bring the price to the one indicated in the header, use the Elec

Checking coupon functionality

The product was provided for writing a review by the store. The review was published in accordance with clause 18 of the Site Rules.

Additional functions of reciprocating saws

Availability and functionality of the support shoe

This device gives the saw a fulcrum on the workpiece, which significantly increases stability and ease of use, speed and evenness of the cut. In inexpensive models, the stop moves along the axis of the tool and is attached in various positions. This makes it possible to adjust the cutting depth.

In advanced models, the shoe can rotate, change its inclination and even bend at the articulation. This device allows you to adapt to a part of the most complex configuration.

Blade replacement mechanism

Only the cheapest models still retain the chuck, which is clamped with a hex key. Quick-release fastening of the saw has become the norm, mostly with one hand and without removing gloves. In the most advanced models, the chuck allows you to mount the blade upside down.

Safety clutch

This device protects the saw and the operator from kickback if the blade jams.

Overload protection

Automatic switches off the engine if it is overloaded or overheated.

Especially useful on household models that are trying to be used in professional mode.

Smooth start

The system is installed on powerful units and protects the power supply network from impulses and current surges. In addition, it allows you to start cutting more accurately.

Electrodynamic brake

Immediately after releasing the power button, the system instantly brakes the rod. This increases the safety and ease of use of the device.

Active vibration reduction

The dynamic system is also installed on high-power saws and serves to neutralize noise and vibration

Advantages of a reciprocating saw

The reciprocating saw has a number of undeniable advantages.

- Ease of use. In essence, this is a familiar hacksaw with an electric drive. Both women and teenagers can confidently work as household models.

- Versatility. A reciprocating saw is an assistant when pruning branches in the garden, during construction, and when dismantling old buildings.

- High performance.

- Ability to work in hard-to-reach places where neither a jigsaw, nor a chain saw, nor a circular saw can be reached;

- Possibility of working on weight.

- A wide range of sawn materials - it is possible to use an electric saw for metal, plastic, wood (including those with nails), concrete, brick and natural stone.

- Greater safety compared to chain saws, grinders and circular saws, less dust and sawdust;

- Easy to maintain and great resource.

Compared to the listed advantages, the disadvantages of a reciprocating saw seem insignificant.

How to make the right choice

To make the optimal choice of a reciprocating saw model from dozens offered on the market, it is necessary, first of all, to clearly answer (and better write down the answers) to a number of questions:

- Purpose of the device.

- Terms of Use.

- Who will use the saw?

- What materials and thickness are planned to be processed.

Knowing the answers to these questions, you will feel much more confident when talking with a consultant in a store. The consultant knows everything about saws, but knows nothing about you. In addition, his task is not to select the most suitable device for you, but to sell you the most expensive model. Only you, having heard information about the devices from a consultant, will be able to compare them with your needs and, based on this comparison, make the best choice.

Popular manufacturers

On the domestic market today you can find up to 200 models of reciprocating saws from different manufacturers, including Russian ones. Some companies have long been known in Russia and are especially popular.

Bosch is a branded manufacturer with a huge range of reciprocating saws of different types. Although Bosch products are not the cheapest, they are known for their quality.

Makita JR 3070CT from a Japanese company is one of the most powerful devices - 1.5 kW and weighing 4.4 kg. It easily copes with any material - from plastic to metal, has a pendulum stroke and an effective anti-vibration system, which allows you to apply no additional effort. Although its price is high, its technical characteristics justify it.

Interskol is a domestic manufacturer that produces high quality tools at prices significantly lower than imported ones. All models of reciprocating saws from the Interskol company have full functionality, which makes them universal in use.

How to choose a reciprocating saw

To choose the right reciprocating saw, you need to compare the parameters and functionality with the answers you have prepared. It is important to pay attention to the following points.

Power

Power determines all other parameters of the device. This is a key characteristic. The power should be enough to work with the materials and thicknesses you choose. In principle, the higher the power, the higher the productivity, the depth of cut, the wider the range of available materials and thicknesses, the longer the continuous operation time and resource.

It should, however, be remembered that a device that is too powerful for occasional home use will also have a lot of weight, dimensions, power consumption, and most importantly, a high price.

Speed adjustment

Adjustment of the stroke frequency of the rod is present in the most budget models. If you plan to cut one type of material, then you can get by with the simplest adjustment - according to the degree to which the power button is pressed.

If a frequent change of material and its thickness is expected, then it is better to consider devices with two-stage adjustment: limiting the maximum frequency with a slide or rotary switch and dialing the speed with the power button, but not more than the limit set on the switch.

Pendulum stroke

The pendulum stroke is designed to speed up cutting and increase blade life. If you have large amounts of work to do, this is a must-have option.

Pendulum reciprocating saw

If you plan to cut extremely complex curved contours from a relatively thin sheet, then the pendulum stroke will be superfluous; you will still have to turn it off.

Support shoe

There must be a support shoe. It increases the convenience and safety of working with a reciprocating saw. If you plan to saw objects of complex shapes in hard-to-reach places, then it is better to choose a shoe with several degrees of adjustment - reach, tilt, rotation.

Blade replacement system

Modern models use a quick blade replacement system. Various manufacturers are promoting their own designs, but all of them must allow the blade to be changed with one hand, and preferably without removing gloves.

High-quality models ensure that the rod stops in the extreme extended position; on budget models, you need to be prepared for the fact that you will have to turn the saw on and off several times before you can find the position to replace the file. You won't be able to pull the blade out by hand.

Smooth start

A soft start system must be installed on powerful devices. This will protect the power supply from current surges, and will also ensure an accurate start to cutting. If the operator does not have great physical strength or work experience, it is better to consider such a system as a household-grade device.

Cutting depth

The cutting depth is related to the engine power. This parameter determines what thickness of material you can cut. If the reciprocating saw you like cannot cope with the boards, beams or sheet material you plan to work with, you will have to choose a more powerful one.

Ease of use

It is very important that the device lies comfortably in the hands, the power cord does not interfere with work, and the weight of the device should not tire the operator’s hands. Some craftsmen rent several different models before purchasing in order to evaluate ease of use in practice and buy the most suitable one.

Power type

It is better to choose a battery type if you plan to use the device outside the home, in the garden or on a construction site where there is no constant power supply. A battery-powered device will also be convenient if you need to carry out small amounts of work in different places on the construction site - then you will save time on dragging extension cords and reconnecting cables.

Corded saw

The network type of power supply is more convenient if many operations are performed close to each other, and the volume of work is large, for example, in a carpentry workshop. In this case, time will be lost just recharging the battery. Mains power is also convenient when a constant cutting speed is required—with cordless machines, as the battery discharges, the power drops.

Feasibility of use

For a long time, the reciprocating saw was not popular in Russia.

Today, the reciprocating saw is greatly inferior to jigsaws and grinders. But in Western countries, especially in the USA, the tool is in high demand due to its simplicity, safety and versatility. Some experts do not see the point in buying another expensive tool, making do with others with similar functions. However, the benefits of a reciprocating saw still outweigh the costs that must be incurred to purchase it.

- Nikolay, 38 years old, Moscow

We almost never buy reciprocating saws, especially builders and repairmen. It is believed that this is a female device, an electric version of a garden hacksaw. I don't agree with this. I work on the construction of low-rise housing and private houses. If we are talking about frames, then here it is simply irreplaceable: cut it off here, then there. The trimmer is cumbersome and can only be used on the ground. The jigsaw has a thin blade. In short, the device is good, it occupies its niche. A professional must have a lot of tools - this is his bread and butter.

- Vadim, 45 years old, Nizhny Novgorod

He built the house himself, with an assistant. Naturally, I stocked up on a good tool to make it easier. There was a cool Bulgarian woman on the farm. A neighbor advised her to buy a disc with teeth so that she could cut boards and timber faster, without using her hands. I followed his advice. True, for work I had to remove the protective casing. It jerks a little when cutting. I worked like this for two days, on the third disc it bit on a nail that unexpectedly found itself inside. As a result, a couple of teeth flew off and the grinder was pulled out of my hands. He escaped with a very big scare and a dislocated wrist. After that I bought myself a “saber”. Health is more valuable.

- Alexander, 65 years old, Krasnodar

I have a large garden, fruit trees. Constant work on pruning, crown molding, knots, etc. There were loppers and a bunch of different hacksaws on the farm, until I bought a reciprocating saw. Now everything is in the barn. Very convenient: any branch, any twig will be sawed off in a moment. I even sawed the trunks - there are no centuries-old oaks, the diameter of the trunk allows. If you have a lot of trees, then that's it.