Metal processing technology does not stand still. There is equipment for performing various technological operations. Metal cutting on a band saw is often used. To cut workpieces, you need to use specialized equipment and know the features of working with it.

Band saw at work

What is a wood band saw

A wood band saw is an electric tool that is used for working with wood workpieces. It is often used for woodworking in carpentry or home workshops. The blade of such a saw is closed - it is represented by a ring on which the teeth are located. Depending on the frequency, shape of the teeth and width of the blade, the saw is able to work with various materials. You can perform the following tasks using a band saw:

- working with logs and workpieces that other types of saws could not handle;

- figured cutting of wood;

- creating identical and mirror elements;

- cross and longitudinal cuts.

My books

As many blog readers already know, I periodically release some useful and goodies, so this time I wrote such an e-book!

The book gives practical recommendations on how to get maximum profit from a sawmill, such recommendations as for example:

Working with technical conditions for the sale of lumber, for example, in winter a third grade appeared in our country, and in the summer (during the season) it disappeared and turned into the first grade;

Wood band saw device

The design of band saws is quite simple and similar for all subcategories of tools. Although the weight and dimensions of high-power saws will be greater than that of home models, the main parts of the mechanism will be the same:

- The body of the saw, also called the frame or bed. All other elements are mounted on it.

- A working surface that has a measuring ruler and a stop. These parts allow you to achieve high precision in your work.

- The engine is the “heart” of the band saw. It converts electricity into rotational motion, which is then transferred to a pulley.

- The band saw blade fits onto a pulley and rotates with it at high speed, ensuring a clean cut.

- The control part with which the operator interacts with the saw.

Types of band saws for wood

Although sawmills are similar, there are several types of band saws. They differ in how exactly the saw blade is positioned, dividing into vertical and horizontal band saws.

Vertical band saws for wood

Vertical band saws are characterized by a vertical blade arrangement. These saws are well suited for cutting wood in woodworking shops, as well as in home workshops. With this tool you can cut materials of different widths and work in any direction. Vertical band saws may vary in size.

When choosing a band saw with a vertical blade, you need to pay attention to the following parameters:

- speed of movement of the working blade;

- blade length;

- availability of several operating speeds;

- the ability to adjust the degree of table tilt;

- maximum cutting depth;

- dimensions and weight of the saw.

Horizontal band saw for wood

There are also models in which the saw blade is located in a horizontal plane. They are popular both among beginners and experienced professionals. Horizontal band saws are great for making crosscuts and miter cuts. There are industrial-scale band saws that can operate autonomously - they are controlled by a computer.

If you decide to purchase a horizontal wood band saw, pay attention to the following characteristics:

- the ability to cut at an angle;

- saw power;

- maximum speed of the web;

- table dimensions.

How to use a band saw on wood?

When working with a band saw on wood, you have to feed the workpiece into the machine yourself, so you need to work carefully and accurately. Place the workpiece against the fence, then mark it. After this, start the saw and let it run for 2 minutes until it reaches the desired number of revolutions. Smoothly serve the workpiece, pressing it well to the table. Make sure that there are no jerks when feeding, and that the saw enters the material gently. If you notice that the saw is jamming, stop working and check that the saw blade is suitable for the material and is not dull. In addition, the speed of the cutting blade may not be suitable. Remember that hard wood requires a lower speed, while soft wood requires a higher speed.

Here are a few points to keep in mind while working:

- Do not pull the workpiece towards you, as this may cause the saw blade to jump off the rollers.

- If you are working with small parts, use a feed board to prevent the saw blade from catching your hands.

- When processing a round workpiece, it is necessary to ensure that it does not rotate when cutting.

- If you work with a bandsaw for a long time, pause to remove shavings and dust from the work surface.

The general rules are:

- You only make money when sawdust is flying out from under the saw!

- There are no trifles in sawing with narrow saws; any deviation from the ideal leads to sad consequences!

- The surest way to ruin a saw is to not dilute it enough!

- There is no point in expecting outstanding results from saws when the sawmill is not working properly!

- Make sure there is light in the sharpening area, this will save you from a lot of trouble!

- It is the individual fit that allows you to achieve outstanding results from an unprepossessing-looking sharpening machine.

- Pay close attention to the shape of the grinding wheel.

How to choose a band saw

When choosing a band saw, there are several key parameters to consider. It is their combination that will determine the capabilities of the saw and the tasks it can perform.

Power

This is one of the most important characteristics. The power of the band saw determines what tasks will be available to it. Low-power band saws are only suitable for domestic use. More powerful models can be used in the professional sphere and in production. Remember that powerful motors require a lot of electricity.

The following classes of band saws can be distinguished:

- If you need a saw for household use, a model with a power of 350-1000 W will suffice. Such a tool is low-demanding and receives power from a regular single-phase network (220 V). It makes little noise during operation and is great for simple tasks or short work. Models with low power levels do not cope well with hard woods.

- For use in workshops or small businesses, band saws with a power of 1-3 kW are needed. They are capable of processing about 10 cubic meters of wood within 1 working day, and also cope well with hard wood. These bandsaws can also be purchased for home use.

- The most powerful saws (above 3 kW) are required for installation in specialized enterprises. They easily cope with hard wood, frozen logs and the thickest workpieces. Models of this class require connection to a three-phase power supply.

Depth and width of cut

The depth of the cut determines how thick the wood the tool can handle. Most often, it ranges from 8 to 50 cm. The depth of the cut is related to power - a weak engine will not be able to handle too much thickness.

The width of the cut affects the maximum width of the workpieces that the saw can process. The most common values are from 300 to 600 mm.

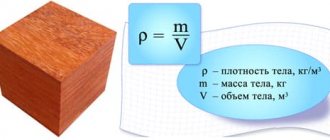

Saw blade parameters

Band saw blades are the working tool of a band saw machine for wood. It is best if it is made of carbon steel. This steel undergoes heat treatment, after which it receives high parameters of hardness and endurance. The length and width of the blade affect productivity and work speed - a wide and long blade can process wide and thick workpieces. If you need to make curved cuts or saw workpieces at an angle, it is best to choose a medium length and width of the blade for cutting.

The saw teeth must be well sharpened - this greatly affects the quality of the cut. The greater the number of teeth in the saw, the smoother the cut will be. The saw blade must have a number of teeth that is a multiple of three, since they have alternate routing - straight, to the right and to the left. The optimal option is 210 teeth with a 3/4-inch pitch or 180 teeth with a 7/8-inch pitch.

Saw blade speed

Soft wood requires a high saw speed, while hard wood requires a relatively low speed. It is best if the saw has the ability to adjust the speed of the blade - such a tool is universal and can work with different species.

Additional Band Saw Features

The presence of additional functions can make working with the saw much more convenient and reduce operating time:

- Quick web tensioning - allows you to do without tools when changing consumables.

- Millimeter scale - makes cutting much more accurate.

- The presence of several stops also makes it possible to increase the accuracy of the cut.

- The rotating and tilting functions of the work table make it much more convenient to carry out curved cuts.

- Illumination of the work area allows you to work comfortably in low light conditions.

Main types of tape

In small sawmills, scrag and rip saws, regardless of the number of heads, blades with a width of 25, 32, 38 and 50 mm are mainly used. Basically, there are two main thicknesses of canvas on the market - 0.035” (0.9 mm) and 0.042” (1.1 mm). Naturally, there are canvases of other sizes, but they are mainly used in specific cases.

Carbon steel blades are most widely used in sawmilling. These fabrics are distinguished by the type of heat treatment to which they have been subjected:

- Constant hardness - a blade with equal hardness across the entire width of the blade. The carbon content in such a material is not high, and this does not allow it to be hardened to a hardness of more than 45-48 units on the HRc scale. This blade works well on small diameter pulleys. However, it has to be sharpened quite often.

- Flex back - Hard Edge - blade with a flexible body/hard tooth. This canvas is called both. In the production of this blade, a tape with a high carbon content is used, which makes it possible to harden its tooth to HRc 63-65. Usually only the upper half of the tooth is hardened, which leaves the saw body practically unhardened and quite flexible. Saw body hardness – HRc 30-33. The advantage of this type of saw is that it holds an edge better while remaining quite flexible. Sometimes manufacturers heat a narrow strip on the very back of the saw, this allows the blade to be straight. Do not confuse such canvases with Hard Back type canvases.

- Hard Back – blade hardened over the entire width. This is the most technologically advanced and difficult to produce type of tape. Its tooth has a hardness of HRc 63-68, and its body HRc 48-53, and the saw body is hardened in a stretched state. High tooth hardness provides good resistance to dulling (the blade lasts longer between sharpenings), and the increased rigidity of the blade body allows sawing at high feed rates. These saws cut smoothly and straight at those feeds on which any other blade would have long ago depicted the “Amur wave.”

- There are also saws with various types of soldering and surfacing, as well as so-called bimetallic saws. All of these types of saws combine excellent flexibility with exceptional tooth resistance, but their high price makes them exotic products and we will not waste time describing them.