When is a chainsaw chain sharpened?

In the process of working with a chainsaw, the chain of any, even the highest quality tool, over time loses its original sharpness and needs to be sharpened. By what signs can you understand that the chain of an electric saw or chainsaw has become dull and it’s time to sharpen it?

Below are the main signs that it is time to sharpen your chain:

- during operation, the saw loses stability, breaks out of the hands and vibrates strongly;

- a chainsaw or electric saw produces only small chips and does not produce large chips;

- the saw part gets stuck in the material, sawing cannot be done efficiently and quickly;

- the chainsaw does not deepen into the wood on its own; in order to make a longitudinal cut, the tool has to be “sinked” into the material with your hands, applying force and pressing the blade;

- during sawing, a curved cut is formed;

- the chainsaw heats up quickly and strongly;

- chain wear occurs much faster;

- fuel consumption increases.

If you notice several of the described signs on your home tool, then it's time to sharpen the chain.

The original chainsaw chain can be sharpened several times, it will retain all its operating properties - cutting sharpness, cut quality, rotation speed along the bar.

A few important tips that will help you avoid sharpening your chainsaw chain longer:

- do not use a new chain with an old sprocket and vice versa;

- if during operation of the chainsaw you have already sharpened two chains, replace the sprocket with a new one;

- the chain must be run-in before full operation of the chainsaw with normal load (run-in is done immediately before sawing, 1 minute at low speeds, and then 1 minute at medium speeds);

- after the new chainsaw chain has cooled, you should check the degree of its tension;

- always use chain saw lube and high-quality oil;

- maintain the normal tension of the links, because during operation the chainsaw is often tilted in different directions, which increases the likelihood of the chain slipping off the bar;

- control the position and direction of the cut depth limiter; after the 3rd or 4th sharpening, check the limiter parameters.

When to sharpen

There are a number of factors that will tell you when it's time to sharpen your chainsaw chain:

- Productivity has decreased. The cutting time has increased.

- There is an excessive load on the saw.

- Increased vibrations.

- Small chips.

For beginners, it is difficult to notice the first 3 moments, so it is recommended to monitor which chips fly out of the cut.

Small chips formed during the sawing process, especially brown ones, are a guaranteed sign of dullness.

Characteristics of chain teeth

Chain teeth have several important parameters. These parameters include:

- cutting link device (consists of a base attached to the chain, a tooth blade with two cutting edges, a depth limiter that controls how deeply the blade cuts into the tree, an end and top blade), the cutting action is performed not by the chain itself, but by the links, that is , teeth. They move on a chain, as if on a base, on a tree, and the link cuts the tree;

- The angle of the end blade that allows the chain to cut the wood (it is because of this angle that wood chips are formed when cutting).

To properly sharpen a chain, the owner needs to know:

- chain metal type (soft, hard, medium);

- chain pitch;

- depth stop distance.

How to properly sharpen a chain depends on these two parameters. The softer the metal of the chainsaw, the more carefully you need to handle the file when sharpening by hand. The upper edge of the file during sharpening should be located at an angle of 90° in the vertical plane and 30° or 10° in the horizontal plane.

Video about the angle of sharpening a chainsaw chain

This video shows how to properly sharpen a chainsaw chain and shows the main parameters of saw chains.

The following video is from a chainsaw owner on how to sharpen a chainsaw chain with your own hands

Rake angles for different types of chains can range from 60 to 85°. The greater the degree of rear angle of the upper chain blade, the more it will be inclined back, the average value of this angle is from 50° to 60°. For the cutting process, the most important indicator (degree) of the rear angle of the upper blade, and the upper blade itself is very important for high-quality sawing.

The main condition when sharpening the chain of a chainsaw or electric saw: cutting performance is directly proportional to the sharpening angle, that is, the higher it is, the better the chainsaw will cut the material. The smaller the sharpening angle, the smoother the tool will move, and the less vibration there will be during operation.

Avoid sharpening angles greater than 35° and less than 25°. In chains for rip sawing, an exception for the sharpening angle is allowed; in these chains, the sharpening angle can be 10°.

Why does the tool become dull?

Each chainsaw has a certain durability period. This is the time from the start of work with a new tool until it becomes inoperable.

Destruction or wear of a cutting tool intended for woodworking occurs due to the impact of a set of forces arising during the cutting process. One of the key ones is friction force. Dulling of the saw chain occurs due to prolonged work, due to the use of a chainsaw for purposes other than its intended purpose.

The amount of wear can be defined as a measure of weight, measured in milligrams. Wear is a parameter that shows a change in the characteristics of the shape and size of the cutting blade. The change in geometric parameters that occurs during cutting, and there is no linear wear, is called blunting.

There are parameters on the basis of which a decision is made about the possibility of further operation of the tool. In particular, when examining the teeth of a saw chain, it is necessary to pay attention to the edges of the front and rear surfaces, the height of the blade, and the wear area. If they are in unsatisfactory condition, it means it’s time to sharpen the chainsaw.

Signs that the saw has lost its sharpness include the following:

- Reducing chip size.

- Using more force to do the job.

Sets of necessary tools, templates and accessories for sharpening chains

The most popular chain sharpening tools:

- round file;

- flat file;

- holder;

- template for depth gauge;

- hook for removing sawdust.

Files for sharpening

Chainsaw chain sharpening machine

Template for controlling the sharpening angle

The sizes of files for sharpening chainsaw chains vary, but in ordinary life, for domestic needs and home use, files with diameters of 4.0 are recommended for sharpening chains in increments of ¼, 0.325″, 3/8″ and 0.404″; 4.8; 5.2 and 5.5 mm. For some chains, cylindrical needle files with a diameter of 3.2 mm are used. For manual sharpening with your own hands, the ideal option would be a file 200 mm long with a diameter of up to 5 mm.

Some manufacturers sell these tools as sharpening sets, or you can purchase them separately. A round file is one of the most popular tools, with the help of which many owners sharpen a chain no worse than on machines. Each set is designed for a specific chain pitch and size. To choose a set for sharpening chains, you need to know these two parameters.

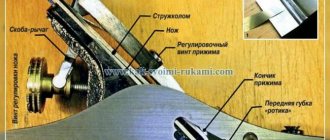

Stihl file holder

Markings are applied to the holder - they help the chainsaw owner determine the correct angle position for sharpening the chain. The holder is installed simultaneously on the upper part of the stop and the tooth, and the round file is placed under it immediately next to the blade. The holder holds the file at the required height; according to the standards, it should rise 1/5 above the blade.

To sharpen a chainsaw chain at home, the bar is secured with a vice or clamp. It is important to keep the tool still while sharpening. The holder is placed on the marking, and then the file is moved along the chain away from you 2-3 times. Each tooth is treated the same way. From time to time, the file is turned to the other side so that it does not grind unevenly.

For convenience, the teeth are sharpened evenly on one side, after which the saw is turned over and aligned on the other side.

Sharpening begins with the smallest tooth, since the length of the remaining teeth must coincide with it. When the blades are sharpened, the stops are processed. Place the template from the kit on the chain so that the stop fits into the hole, and grind off all protruding edges with a flat file from the sharpening kit.

Other chain sharpening devices, sharpening tools and devices:

- roller sharpening device;

- files from various companies (round, flat);

- holders with a file;

- handles and guides for files;

- plastic cases, containers for storing tools;

- needle file - a small file, an oblong-shaped device with a diamond cut, most often needle files are used for filing very small parts, often sold in sets.

Saw chain depth limiter

If you do not have experience sharpening a chain, we recommend that you use special templates for adjusting the depth stop and setting the correct sharpening angle of the cutting tooth, which are included in chain sharpening kits. Depth gauge templates are also called gauges.

The depth of the stop must be checked every third sharpening of the saw chain.

1. To correctly measure the saw chain stop, install the template so that only one stop fits into its groove.

2. If the chain stop extends beyond the boundaries of the template, it must be ground off with a flat file. Be careful not to allow the limiter to be too low relative to the template.

When working with a flat file, do not grind down other elements of the chain; work only with the template.

The saw chain depth limiters cannot wear out while the chainsaw is running; if you notice wear, replace the chain.

Popular models of inexpensive sharpening machines

Popular manufacturers of inexpensive chain sharpening machines: Dnipro, Einhell, Sadko, Vitals, Forte, Intertool, Eltos, Zenit, Grand, Stern, Temp.

Among the variety of models, each owner of a chainsaw or electric saw can choose the tool that suits him. Below is a rating of the best inexpensive machines for sharpening chainsaw chains; these machines have received many complimentary reviews from owners. How much will this device cost? The cost of machines from this category is from low to medium. There are many models in this price range that do an excellent job of sharpening chains for electric and gasoline saws.

What is the sharpening angle and why is it important?

The sharpening angle is determined by the relative position of the edges of the blade. The sawing characteristics of the chainsaw depend on its value. The horizontal cutting edge is responsible for immersing the blade into the wood and forming a cut. The end blade cuts the wood fibers laterally. Entire research laboratories of manufacturing enterprises are working to determine the optimal sharpening angle.

It has been experimentally established that high sawing characteristics are demonstrated by chains with an upper cutting angle of up to 60 degrees. The side blade is sharpened at an angle of up to 85 degrees. With the highest possible angles, the tools are better at cross-cutting logs. For longitudinal cuts, the chain is sharpened at angles of about 10 degrees.

Important

: Blade geometry only matters if the depth gauge is set correctly. If you sharpen this element incorrectly, the chainsaw will vibrate during operation and break out of your hands. The limiter is adjusted according to the template.

Types of sharpening chainsaw chains and proper work with them

Next, we will talk about several popular methods of sharpening a chain, which can be done both at home and in production.

Manual sharpening with a file at home

Manual sharpening is considered the most economical, budget-friendly, for this you only need a file, which the owner has in every home; if he doesn’t have one, it is inexpensive and is sold at any construction market or in a building supply and tool store. For a chain size of 1.3 mm you will need a file with a diameter of 4 mm, for a chain size of 1.6 mm you will need a file with a diameter of 5.2 mm.

A flat file can be used for the tooth stops. The sharpening template is attached to the element being ground.

Steps for manually sharpening a chainsaw chain at home:

- secure the chain (bar) so that it is completely motionless;

- do not change the sharpening angle during the entire sharpening;

- make 2-3 forward movements with the file using light pressure;

- turn the file in different directions;

- Sharpen according to the size of the smallest tooth.

How to sharpen a chainsaw chain with a file with your own hands - about this video below:

Professional sharpening on a machine

Sharpening on a machine can be done with a manual machine or a professional machine.

Professional machines operate from the network. The principle of sharpening is almost the same as with manual sharpening:

- The chainsaw chain is fixed in the guides;

- Next, adjust the width of the groove and select the angle;

- lower the sharpening disk;

- The chain is moved along the holder, clamped, and each tooth is processed.

The sharpening element in professional machines is an emery stone. A good automatic machine is not cheap, so professional sharpening equipment is mainly found in service centers and workshops. Buying this for home use is not rational.

Useful tips

You can increase the service life if you alternate manual sharpening with the use of a special machine. The latter allows you to align sharpening angles on the machine as accurately as possible. The stitching depth should not be large.

It is necessary to observe safety measures that allow you to cut wood of any size with maximum efficiency and with a minimum level of danger to humans:

- Before assembling the chain tool and installing the headset, it is recommended that you read the instructions for use. This is due to the fact that each tool has its own characteristics.

- When working with a saw, you must wear gloves and safety glasses.

- For work, it is recommended to choose close-fitting clothing made from natural dense materials and the most reliable shoes.

- It is necessary to cut wood using a chainsaw in a stable and safe position, and the material itself must also be positioned as stably as possible. Installing a toothed stop on the log will help ensure stability.

- During operation, the saw must be held with both hands and the cutting process must be constantly monitored.

Modern chainsaws are used in domestic and industrial settings. At the same time, it is important to maintain the productivity and high efficiency indicators of the tool, which directly depend on the condition of the sharpened chain set.

How to sharpen a chainsaw chain with your own hands on the RedVerg RD-CS100 machine: video instructions

We will teach you how to properly sharpen a saw chain on an electric machine. In this video, a technical expert from TMK.

Sharpening a saw chain from a chainsaw on a machine purchased from OBI, my detailed instructions

Review Chain sharpening machine VIHR SZTS-200

Buy the VORTEX machine SZTs-200: https://goo.gl/6jJZVo Machine for sharpening chains SZTs-200. Rated power 200 W. Frequency.

A lesson on sharpening a chain from a real sawyer! How to sharpen correctly, improvements and tricks.

The video describes the process of sharpening a chain on a Diold machine. Subscribe to the channel - there will be new ones soon.

✅ TO THE TUBE. Dnipro-M SG-55M chain sharpening machine / Dnipro-M SG-60P / how to sharpen a chainsaw chain?

HELLO, I DECIDED TO COMPARE THE CHAIN SHARPENING MACHINE Dnipro-M SG-55M, AND I TOOK A SHARPENING MACHINE OF THE SAME COMPANY.

Do-it-yourself chainsaw sharpening

The main points you need to know when sharpening chainsaw chains yourself. In addition to the sharpening angle.

Proper chain sharpening

I show and talk about how to properly sharpen a hook chain for a saw on a machine!

Chain sharpening machine Tatra Garden ECS 185. How to use

“Hello, I want to show off my new purchase, a Tatra Garden ECS chainsaw chain sharpening machine.

Sharpening a chain on a chainsaw with your own hands

Working on a saw chain sharpening machine

Working on a sharpening machine for saw chains.

Chain sharpening machine Vikhr STSZ 200

In this video, construction market seller Ivan will talk about how he learned to earn extra money.

Read also: Walk-behind tractor with plow photo

Saw chain sharpening machine REZER EG85-C

Good day to all! ;))) Just yesterday I purchased such a machine for sharpening chainsaw chains.

Machine or File? What is the REAL resource of the saw chain?

Machine or File? Sharpening a saw chain in practice using the Bosch GKE 40 BCE electric saw as an example. How much is realistic?

Chain sharpening machine INTERTOOL DT-0850 – correct chain sharpening!

Sharpening a chainsaw chain or electric chainsaw has never been so easy and accessible to everyone! This.

Sharpening chain for rip sawing

VKontakte page: https://vk.com/mazai75 Masterova Forum: https://forum.woodtools.ru/index.php?topic=55700.msg1030146#msg1030146 Music: .

What machine to sharpen a chain with | Einhell GC-CS 85 | Soyuz TSS-60013 | Buy chain sharpening machine/machine

Chain sharpening machine Einhell GC-CS 85 is a good machine for sharpening chainsaw chains - comparison with the SOYUZ TSS-60 machine.

Oregon Power Sharp, chain sharpening in 5 seconds

Sharpening a chain on a chainsaw takes just five seconds. But provided that you have a sharpening machine.

A device for chainsaws will allow you to sharpen a chain in 4 seconds without removing it from the bar

DIY chainsaw sharpening machine

Thank you all, please comment and recommend. I DO NOT PARTICIPATE in affiliate programs. Enjoy your viewing everyone.

07 vermiferma.com Sharpening a chainsaw chain using the Whirlwind SZTs-200 machine

We prepare firewood to heat the worm house. You need to sharpen your saw chain. We use a sharpening machine.

Stihl chain sharpening.

Basics of sharpening saw chains...

Sharpening the chain. Sharpening the cutting and limiter. Errors, nuances, features. Everything is extremely detailed.

Sharpening a chain using the example of a Stihl chain. The first half of the video is theoretical, the second is practical, watch the second.

chainsaw chain sharpening.

How I sharpen chains for a chainsaw. Website: https://www.master-dom2011.com/ email: Odnoklassniki: https://ok.ru/?

I bought a chain grinding machine (review)

DEVICE for sharpening chainsaw chains

To sharpen STIHL's chains, I made a DEVICE.

Sharpening a saw chain on a Rezer machine.

Chainsaw chain sharpening machine.

Test device. very comfortable.

Sharpening the chain. Basic mistakes when sharpening.

Watch my videos: How not to overheat a tooth https://www.youtube.com/watch?v=T13ka_ZhX3g About the cutting depth limiter.

Chainsaw chain sharpening machine

A machine made by yourself at minimal cost.

Sharpening a chainsaw CHAIN to FACTORY sharpness

We sharpen the chain on a chainsaw using a simple device - the result is no worse than factory sharpening.

Test drive of the Rezer EG235-CN sharpening machine

Sharpened the first chain on a Razer EG235-CN machine. Of course, I don’t have sharpening skills yet, as you can see in the video.

2 MINUTES TO SHARPEN CHAINSAW CHAINS

In principle, it turns out fine once you acquire the skill.

✅ The secret of professional saw chain sharpening from Stihl.

sharpening#tools#stihl#chain#DIY How to sharpen a chainsaw saw chain in the best way? Yes, so much so.

Modification of a sharpening machine for saw chains.

Modification of a sharpening machine for saw chains. Elimination of backlashes and bringing to a working condition.

Sharpening a chainsaw chain

How to sharpen a chain for a Stihl 361 and other chainsaws using a special Oregon 519789 sharpening machine.

sharpening machine for chainsaw chains.

sharpening machine for chainsaw chains. .Chinese sharpening, for chains. I've been using it for several years and it doesn't sharpen the chains.

Sharpening a chain saw with a grinder

For swearing and insults in the comments - BAN. My solution to the problem of sharpening chain saw teeth. Data.

Testing a machine for sharpening chainsaw chains Kettenschärfgerät FSG 85 D11

Friends, I am testing a chainsaw chain sharpening machine (Kettenschärfgerät FSG 85) D11. It's just cheaper to sharpen the chain.