The CNC wood laser machine is used in many areas of production. Therefore, it is important to know its structure, features, and advantages.

Do you have a CNC laser machine for wood, or do you want to purchase one? This is not surprising since CNC laser is a popular machine that is used in many areas of manufacturing.

Souvenirs, furniture, promotional items - this is not the entire list of items that can be made with its help. Laser machines today have become an excellent alternative to manual cutting, burning, carving, which has greatly simplified these processes and reduced the time spent on work.

Choosing a laser machine for working with wood

Of course, when choosing a machine you need to be extremely careful and pay attention to even the smallest details, since the machine is not a cheap thing and will serve you for many years. When choosing a laser machine for wood, there are two main characteristics:

- Working field size. Think about what kind of workspace you need and for what tasks it will be used.

- Tube power. This element will depend on the thickness of the material being processed. If the machine is used for cutting plywood, then from my own practice I can say that you should not use more than 85 W (this includes engraving). Since such power can cope with a material thickness of approximately 10 mm.

I can offer another option, more economical. If the requirements are cutting and engraving, then it is quite possible to buy two different machines respectively. Yes, and for engraving you will need a smaller field and a lower power tube (even 45 W), but there is one drawback - a decrease in productivity.

How to calculate the cost of laser cutting?

What determines the cost of laser cutting of plywood:

- Initial cost of equipment

- Depreciation and consumables

- Renting premises

- Communal payments

- Employee compensation (or your salary)

For those who are too lazy to read))) A good friend of mine voiced and posted a video on his YouTube channel based on this article. If you prefer to watch a video, go to his channel! By the way, other interesting projects will soon appear there. Go ahead and subscribe.

Equipment

I actually got it for free, so I didn’t take into account the original cost. I took its cost into account only in depreciation.

Depreciation and consumables

Any machine requires maintenance and breaks down over time. We take the average value that the purchased equipment should work for 5 years, after which it will require replacement (in fact, the machine can work longer). This means that in 5 years I must save its full cost.

My laser cost 550,000 rubles at that time. 5 years is 60 months. It turns out 9170r/month.

The main consumable is the laser tube. 100W costs approximately 30,000 rubles. Its resource is indicated at 10,000 hours. But in reality, most often it turns out less, especially when working in non-ideal conditions, so we take 4000-5000 hours. In a month with such a load, we cut 222 hours.

It turns out that the tube will have to be changed approximately every 2 years. Or 1250r/month.

For other materials and unforeseen expenses: power supply (it has a longer lifespan than the tube), lenses, mirrors, lubricant, etc. we'll set aside another 1000 rubles/month.

Total: 11420r/month.

Rent + utilities

This is where the ambush in our agreement with the state lay. Because we could not rent a “corner” in the company or a garage. Therefore, for two small premises we had to pay 30,000 rubles per month, plus 4,500 rubles per month for a communal apartment (on average).

Salary

I worked myself, but I immediately took into account the option that someone would work instead of me. The average salary of a CNC machine operator in the province is 25,000 rubles/month.

In total, it turns out that monthly expenses are almost 71,000 rubles. Your figure will be lower due to the possibility of renting another room and possibly other equipment.

As you can see, most of the costs are time costs. Therefore, before calculating the cost, we should select cutting modes.

In my case, a large machine cut plywood:

- 3mm – 25mm/s

- 4mm – 23mm/s

- 6mm – 13mm/s

The speeds could be higher, but, unfortunately, the quality of plywood in Russia leaves much to be desired.

So, let's say we have a 10-hour working day with a 5-day week (approximately 22 working days per month) and all this time our machine is ideally loaded. Let's calculate how much and what kind of plywood we can cut in a month.

- 3mm: 25*60*60*10*22=19,800,000mm=19800m.

- 4mm: 23*60*60*10*22=18216m

- 6mm: 10296m.

But these numbers are ideal. If you turn on the machine in the morning and it cuts at the same speed all day. Without taking into account accelerations and decelerations, material laying, uncut parts, etc. Therefore, you can safely subtract 30-40% from these numbers.

So in a month we can cut:

- 3mm: 12870m

- 4mm: 11840m

- 6mm: 6692m

Now we divide the costs by the total footage per month. The cost of laser cutting of plywood is:

- 3mm: 5.5r/m

- 4mm: 6r/m

- 6mm: 10.6r/m

For other materials and engraving, the price is calculated accordingly. For engraving, you select the time it takes for him to make 1cm^2 of engraving and also estimate the cost.

In fact, my prices are a little higher than they really should be, because... I had two machines in one room. This means the rental cost is divided between both CNC lasers. And the machine operator also doesn’t just sit while cutting, but makes layouts, paints, assembles products, etc.

Machine device

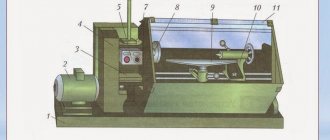

The entire design of a numerically controlled machine consists of the following elements: a bed, a horizontal work table or tabletop, a mobile portal with tools located above the working surface (equipped with a laser), a laser unit, which includes a laser tube, emitter head, lenses and mirrors

The design also includes an electric motor that drives the laser. This element is controlled by a special computer program.

The machine operation scheme is as follows:

- The flow of a mixture of nitrogen, carbon dioxide and helium into the tube.

- Voltage is supplied to form the laser beam, which occurs through a transformer.

- Focus the beam using lenses and a mirror.

- Processing the workpiece with a laser head.

- Constantly cooling the tube with water as a way to protect against overheating.

Principle of operation

To operate, you will need an energy source, an active medium, and an optical resonator.

It all happens something like this: with the help of a source, crystals that carry a certain charge enter the active medium. Next, they (the same crystals) attract similar particles to themselves. The crystals begin to move more quickly due to the amplifier, often collide with atoms and knock out new crystals. Through the resonator they go out in a narrow beam, which we actually see.

Types of equipment

Different types of laser machines may differ in their functionality, control method, power and dimensions.

By functionality

According to the declared functionality, there is the following division. Firstly, these are engraving machines with a relatively weak light beam, sufficient only for performing superficial operations. If they are reconfigured, accompanied by an increase in wavelength, such mini-units can be used for cutting plywood sheet blanks and veneer.

And, secondly, this is equipment with increased laser beam power, capable of not only cutting wood, but also milling it. They also have an engraving function, which is implemented by reconfiguring the laser beam in terms of power.

By type of control

According to this feature, all known examples of laser cutting machines are divided into the following classes:

- manually operated wood processing machines, which belong to the category of the simplest, cheapest and most affordable units. Despite this, unique products can be made with their help;

- more expensive numerically controlled devices that provide high quality processing and engraving;

- universal machines.

The latter type of equipment combines the capabilities of manual and automatic control.

By power and size

Based on these parameters, the following three types of equipment for cutting plywood are distinguished.

The first type includes a compact desktop device for engraving work with a stated power of up to 80 watts. This machine is designed for the production of small-sized souvenir products; it can also be used for cutting not very thick sheets of plywood.

Note! Such mini laser machines can be used on small factory sites. For working at home, it is advisable to choose them.

Professional models with a power from 80 to 195 watts and a cost of 150 thousand rubles are designed for cutting wood and plywood. They have significant dimensions and are used for the production of serial products in small batches.

And finally, samples of industrial equipment for wood processing, capable of not only cutting plywood, but also boring blanks and engraving surfaces. These machines are quite impressive in size and can be installed in large woodworking factories.

Certain rating samples of laser technology can combine several functions at once, which significantly facilitate the process of processing plywood products.

Advantages of laser cutting and wood engraving

pros

- economical use of processed material

- low cost of final products

- high processing accuracy with minimal error up to fractions of a millimeter

- greater repeatability for large runs

- safety and fire protection due to cooling

- perfectly smooth cutting edge

- various shades of cutting edge and engraving

- absence of deformations, sagging, defects, defects during processing

Minuses

- you are limited by the width of the working field of the laser machine if you purchase small or medium format equipment

- If your laser machine does not have options such as a "lift table", then you cannot process large and cylindrical workpieces with a rotary device

- If your laser machine does not have a through table, then you will not be able to process long pieces of wood. You will have to pre-cut them to the size of your desktop

Engraving of glasses, glasses, wine glasses, glass on a CO2 laser machine

To engrave on dishes, you need to have rotary axes. The most convenient would be a cam rotary axis, but it should be taken into account that closed cylindrical objects, as well as glasses and wine glasses with sharply changing diameters, cannot be engraved on it. For such purposes, a roller rotary axis is better. Materials are usually purchased from IKEA stores (this is not an advertisement).

Customers who order engraving on glasses are often concerned about the fact that the inscription may be erased in the dishwasher. If you are planning to engage in this area, it is advisable to dispel such fears by conducting tests yourself.

Cam Rotary Axis for Laser Machine

The device of a laser machine for wood

It is also important to pay attention to the power of the laser tube, which determines the speed and quality of the cut.

If you process large materials, for example, barrels, boxes or boxes, then it is important to have a lowerable work table in your wood laser machine. This option will also be useful if, for example, you engrave round objects, such as bamboo blanks or rolling pins, using a rotary device.

A work table with the ability to pull material (through) will be useful when processing workpieces whose length extends beyond the work table.

Let's analyze the control system. There are machines with a simple, single-task control system (M2 board), which understands only one task in one run, and multi-task control systems, for example, Ruida, with which the machine can cut and engrave simultaneously within one run.

When laser cutting wood, take care of good exhaust, which, together with air supply to the nozzle, improves the quality of cutting materials and provides excellent smoke removal, which is necessary to reduce the loss of beam power during transmission and keep the optical elements of the machine clean.

Pay special attention to the linear motion system of your laser wood cutting machine. All machines whose axes move using fluoroplastic rollers are not professional and precise equipment, but are considered more devices for home use and hobbies, since fluoroplastic rollers wear out over six months of intensive use, and therefore the accuracy of movement of the laser head is impaired. All machines whose movement system is rail guides are insured against this defect, due to the fact that needle bearings slide along the rails. With constant good lubrication, they can last forever!

Business plan: laser cutting of plywood

How to organize a business using a laser machine? Let's consider a case using the example of a production facility where plywood is cut.

You can install a laser device in a small warehouse, but fire safety standards must be taken into account. Then you need to find reliable suppliers of consumables, that is, the plywood itself. Every time you buy a batch of plywood, you should check the quality of the board - the accuracy of the design, the accuracy of processing and the strength of the finished product depend on this.

Before implementing the project, you should develop a cutting model on a computer, and then transfer the data to the machine.

The financial aspects of a business depend on the goals that the company sets for itself and the equipment chosen. As an example, let’s evaluate what you need to buy when using a large, powerful (100 W) LaserSolid 1080 Pro laser machine. The price of the device is 465,000₽.

The workroom must have a powerful exhaust hood, since cutting plywood produces a lot of dust and smoke. Space should be provided not only for the machine, but also for the materials used. At a minimum, you will need a room of 10 square meters. m. The cost of renting or purchasing premises depends on the region.

In addition to the machine, it is necessary to purchase a circular saw, because plywood sheets are much larger in area than the working area of the machine. You will need a grinder to remove carbon marks after cutting. We will also add the cost of the plywood itself.

Buy a laser machine for wood

We answer all calls, letters, messages and always welcome guests.

Call

+7 +7 +7 + Viber, WhatsApp, Telegram

Come visit

St. Petersburg, st. Respublikanskaya, 22, letter E, room 4SH

We are working

Mon.-Fri. from 9:00 to 19:00 (Moscow time)

Having a numerically controlled wood laser machine at your disposal is a rather tempting prospect, as it will even allow you to open your own small business for decorative processing of lumber.

The main advantage of laser cutting or burning is that you, in fact, do not even need the talents of an artist to sketch on the part being processed - special programs cope with this perfectly.

Pictured: Laser-cut filigree design

They can be embedded in the machine itself, or added from third-party media such as a removable disk or flash drive, and we will talk about this now, and also offer you a video in this article on this topic.

Advantages and disadvantages

Modern machines have many advantages:

- High accuracy. Engraving or cutting using a machine is considered a highly precise process. The thickness of the cut is no more than 2 mm. To cut or engrave yourself, you no longer need to exert physical effort and use improvised tools.

- High efficiency. The speed of work allows you to minimize the time when performing various volumes of work, which allows you to save energy resources.

- Economical. This indicator applies to both material consumption and energy consumption indicators. Due to high precision of work, laser machines economically save wood, reducing waste to a minimum.

- Versatility. In addition to cutting, the machines can perform engraving work.

The main disadvantage is only one factor - cost and inaccessibility. Not all hobbyists will be able to afford to buy such an expensive laser wood processing machine, but everyone can try to make it with their own hands.

Approximate cost for laser cutting services. Prices are indicated in rubles per 1 linear meter of cut. The price of engraving is indicated in rubles per 1 square centimeter.

Artistic laser burning

How does this happen

Note. For lumber, a wood laser means the ability to cut and engrave, which are needed mainly for decorative elements. With the help of such machines, entire architectural ensembles and buildings are decorated, as well as various gifts and souvenirs, New Year's wooden toys and arts and crafts, baguettes and panels.

Laser wood processing on a CNC machine

- By and large, any wood can be processed on CNC laser machines, but the instructions still give preference to cedar, beech, alder, cork and any valuable species. In addition, laser cutting on plywood and MDF is very often practiced.

- The laser cutting process, at its core, is also burning, only more precise and focused, which is possible when choosing suitable optics - the processed surface simply burns and chars. But this, for obvious reasons, causes heating of neighboring areas of wood, so a compressed air supply is installed above the cutter and areas near the cutting zone are exposed to only low thermal stress.

- But if hard woods can still be processed without compressed air, since they have reduced thermal conductivity, then for soft woods, MDF or plywood, such cooling is a production necessity.

- The charring of the edges of the cut during processing turns out to be brown in color, so they can be used as an element of decoration and emphasizing the lines of an ornament or picture.

Note. Unlike milling on CNC machines, where the part must be well fixed, laser machines do not require this. The workpiece is simply placed on the work table in the right place and this significantly saves time spent on finishing materials.

Review of FMARK models from Germany

Engraver FMARK NS

A few recommendations for choosing plywood

Most often, indoor plywood of the “FK” brand is used for laser processing (the layers are glued with urea-formaldehyde glue).

It is not recommended to use FSF (moisture resistant) plywood. The laser cuts it quite hard. This plywood, with a thickness of 4 mm, is cut using the same modes that are required for cutting 12 mm FC sheets. In other modes it starts to burn.

The use of bacilite plywood is strictly prohibited. It is processed exclusively with waterjet or milling.

The ideal solution is to use aircraft grade plywood. Highest strength, easy to process. Available in 2 mm thick sheets.

When choosing plywood, it is recommended to adhere to the following rules.

- Sheets must be dry and even.

Lead sheets should not be used, as this will affect the quality of processing.

- Control uniform sheet thickness over the entire area.

Otherwise, you end up with a material with a wavy structure. When engraving it, the laser beam is not focused. The quality of work is significantly reduced.

- Try not to work with workpieces whose thickness exceeds 10 mm.

Plywood is glued veneer sheets (most often the adhesive composition is based on formaldehyde resins). The laser does not cut resin. As a result, defects arise at points of excess of this material.

In addition, thick workpieces are cut at lower speeds. This can cause the edges to become charred.

- Select material without knots.

The optimal solution is to use first and second grade plywood. It initially has no knots. The latter laser cuts poorly. This may ruin the final work.

- Hardwood plywood is much lighter in color.

It produces better burning. The cut lines are darker and not as deep.